Proper mine dewatering pumps are the lifeline of any mining operation, much like a heart is to the human body.

They ensure the consistent removal of unwanted water.

Without effective dewatering solutions, mining processes can face debilitating interruptions, resulting in significant financial losses and decreased efficiency.

Introduction to Mine Dewatering Pumps

Mine dewatering pumps are essential for all mining operations.

By efficiently removing excess water, these pumps maintain a safe working environment and ensure uninterrupted mining activities. High-performing dewatering systems are crucial for minimizing operational downtime and mitigating risks associated with water accumulation, which can adversely affect equipment and worker safety.

Traditionally, mine dewatering has been a demanding task, requiring robust and reliable equipment. Technological advancements have now produced pumps that offer enhanced durability and efficiency, capable of handling large volumes of water while withstanding harsh conditions.

Selecting top-rated mine dewatering pumps involves evaluating factors such as capacity, efficiency, and operational cost. Implementing the most suitable pump technology for your mine not only enhances productivity but also contributes to the sustainability and profitability of your mining endeavors.

Key Features of Mine Dewatering Pumps

State-of-the-art mine dewatering pumps prioritize durability, a hallmark of exceptional engineering, leaving no room for compromise. These pumps boast advanced materials and innovative designs to endure the challenges of fluctuating water levels and abrasive particulates, ensuring uninterrupted performance and extended service life. Furthermore, they offer remarkable efficiency, thanks to energy-saving technology that reduces operational costs and minimizes environmental impact, making them a strategic investment for any mining operation striving for excellence and sustainability.

High Efficiency and Performance

Achieving high efficiency and performance is crucial in selecting mine dewatering pumps.

Energy-efficient pumps can significantly reduce operational costs while contributing to environmental sustainability.

Modern mine dewatering pumps are designed to deliver unmatched efficiency, ensuring that water removal processes are both rapid and cost-effective. These pumps employ cutting-edge technology to optimize energy consumption without sacrificing performance.

Investing in high-efficiency mine dewatering pumps not only lowers your operational costs but also extends the service life of the equipment. This, in turn, maximizes your return on investment, making it a prudent choice for forward-thinking mining operations.

Durability and Robust Construction

Your mine dewatering pumps must last.

Exceptional durability begins with robust construction. High-quality materials such as corrosion-resistant stainless steel and abrasion-resistant rubber are often used, ensuring these pumps can withstand the harshest environments. Additionally, advanced engineering processes enhance the overall resilience of these units, reducing the frequency of costly maintenance.

This reliability is invaluable.

You need dewatering pumps built to perform—day in, day out. That is why you should prioritize pumps specifically designed to endure prolonged exposure to abrasive materials, high pressures, and extreme temperatures.

Finally, the latest innovations in construction materials and techniques in top-rated mine dewatering pumps mean they are more durable than ever before. This longevity ensures a lower total cost of ownership and dependable performance, which are crucial for continuous and efficient mining operations.

Easy Maintenance and Operation

Your maintenance efforts can be dramatically minimized.

Modern mine dewatering pumps are designed for easy operation. From intuitive control panels to features that simplify routine maintenance tasks, these pumps prioritize user-friendliness without compromising effectiveness. For instance, many models now include self-cleaning filters and automated alerts for preventive maintenance.

Simplifying maintenance maximizes productivity.

You can perform quick inspections due to easily accessible components. This ensures less downtime and more consistent operation, which is essential for maintaining productivity in demanding mining environments.

Additionally, comprehensive user manuals and training materials are readily available to help you understand the specifics of pump maintenance and operation. Coupled with reliable customer support, you’re empowered to keep your dewatering equipment running smoothly with minimal hassle.

Ultimately, the ease of maintenance and operation in top-rated mine dewatering pumps translates into extended equipment lifespan, reduced operational costs, and increased efficiency. These advantages contribute significantly to the success and sustainability of your mining activities.

Types of Mine Dewatering Pumps

Choosing the right mine dewatering pump is critical for maintaining efficient operations and ensuring the safety of your mining site. Various types of mine dewatering pumps are available, each designed to suit different scenarios and mining conditions.

Centrifugal pumps are among the most common, known for their efficiency and high flow rates. These pumps are ideal for transferring large volumes of water quickly. Positive displacement pumps, on the other hand, are excellent for handling slurries and conditions requiring a steady flow rate. Also available are submersible pumps that excel in deep water levels, offering versatility and reliability in diverse mining environments.

Centrifugal Pumps

Centrifugal pumps are a mainstay in the mine dewatering industry, renowned for their high efficiency and robust performance.

These pumps utilize a rotating impeller to move water through the system, enabling rapid dewatering and high flow rates. Ideal for large-scale mining operations, centrifugal pumps handle substantial water volumes, which is essential in consistently maintaining dry and safe mining conditions. Moreover, they are known for simple mechanical design, ensuring ease of maintenance and longevity.

Typically, centrifugal pumps are chosen for their capability to perform in demanding environments. Their robust design allows them to withstand harsh conditions, including abrasive materials often present in mine water. This reliability ensures continuous operation, minimizing downtime and enhancing overall productivity in your mining project.

Choosing quality centrifugal pumps for your mine dewatering needs guarantees efficiency and durability. By investing in top-rated mine dewatering pumps, you significantly enhance the operational effectiveness of your mining activities, ensuring a safer and more productive working environment. Leveraging these pumps’ advanced technology and sturdy construction will undoubtedly support the long-term goals of your mining operations.

For more information, visit Dewatering Pumps.

Submersible Pumps

Submersible pumps excel in challenging conditions, making them indispensable tools for mine dewatering and other tough environments.

These pumps, submerged directly into the liquid being pumped, provide distinct advantages, including enhanced efficiency and reduced need for priming. Due to their design, submersible pumps minimize suction head issues, crucial for optimal performance in deep or flooded mines. Their deployment ensures consistent dewatering, sharply reducing the risk of operational interruptions.

Notably, submersible pumps are built to endure harsh conditions. With robust construction and specialized materials, these pumps resist corrosion and wear, allowing them to handle abrasive and aggressive mine water effectively.

Selecting submersible pumps aligns with professional standards of maintaining reliable mining operations. As a trusted choice for mine dewatering, these pumps offer a resilient solution, safeguarding both your equipment and workforce while promoting uninterrupted productivity. Their integration into your dewatering strategy ensures a future-proof approach to mine management.

For more information, visit Dynapro Pumps.

Positive Displacement Pumps

Positive displacement pumps, unlike their centrifugal counterparts, excel at handling varying viscosities and solid-laden liquids without compromising on flow efficacy.

These pumps, in mine dewatering applications, rely on a consistent volume per cycle mechanism, delivering steady flow rates. When you require precise control over dewatering processes, positive displacement pumps stand unrivaled, particularly in challenging conditions. Their ability to maintain performance despite fluctuating pressures makes them indispensable for complex mining operations.

Notably, these pumps can operate at a constant efficiency regardless of the system’s pressure head. By mitigating risks associated with clogging and wear, you can ensure extended service life and reduced maintenance costs, bolstering the overall efficiency of your mining operations.

Deploying positive displacement pumps in your dewatering infrastructure represents a strategic investment in reliability and longevity. By optimizing liquid handling capabilities in demanding environments, these pumps prevent costly downtimes and ensure that your mine maintains maximum operational efficiency. This approach reflects a commitment to sustainable, high-performance mining practices.

Applications of Mine Dewatering Pumps

Mine dewatering pumps play a pivotal role in ensuring safe, effective mining operations, particularly in challenging environments. These pumps efficiently remove water accumulation, maintaining dry conditions essential for continued excavation. Beyond enhancing operational efficiency, they also offer critical environmental protection, preventing uncontrolled water discharge that can harm local ecosystems. By choosing top-rated mine dewatering pumps, you ensure your mining activities proceed seamlessly, safeguarding both personnel and resources while upholding stringent regulatory standards.

Open Pit Mines

In open pit mining, effective dewatering is crucial to maintaining operational efficiency and safety.

- Challenges: Large-scale water inflow, unpredictable weather, groundwater control

- Solutions: High-capacity centrifugal pumps, submersible pumps, monitoring systems

- Benefits: Reduced downtime, improved mine safety, optimized excavation processes

- Considerations: Pump reliability, energy efficiency, ease of maintenance

Implementing an advanced mine dewatering system in open pit mines minimizes risks associated with water ingress.

By ensuring a controlled water management strategy, you enhance productivity and prolong the mine’s operational lifespan.

Underground Mines

Underground mining presents unique challenges in dewatering efforts.

Dealing with confined spaces and significant water ingress requires robust solutions.

Since 2016, innovative technology has revolutionized underground mine dewatering, providing highly efficient pumps that withstand harsh conditions.

However, it’s not just about having the right equipment; the strategy behind water management is equally crucial for success.

Selecting top-rated mine dewatering pumps ensures you maintain optimal safety and productivity underground.

Water Management Systems

Effective water management is crucial for mining operations.

Proper systems help you control and utilize your water resources. You gain significant advantages by implementing advanced water management technologies, such as top-rated mine dewatering pumps. These systems are designed to handle the most challenging conditions and sustain optimal performance levels crucial for maintaining operational efficiency.

Systems provide immense operational advantages.

Think of it as an investment that pays off – not just in terms of reducing operational risks but also in enhancing environmental compliance and sustainability targets.

With reliable systems in place, you ensure the uninterrupted operation of your mine, balancing productivity with environmental stewardship. You are prepared to meet any challenges that arise and sustain success throughout the lifespan of your mining project.

Benefits of Using Mine Dewatering Pumps

By integrating top-rated mine dewatering pumps, you unlock an array of operational benefits, leading to enhanced productivity and safety. These pumps are engineered to manage water efficiently in various mining conditions, reducing downtime and preventing hazardous flooding. Moreover, with state-of-the-art technology, they require minimal maintenance, ensuring that your investment delivers long-term reliability and cost savings. You are better equipped to handle environmental regulations, pushing your operations towards sustainable practices while maintaining high performance.

Improved Safety

Integrating top-rated mine dewatering pumps significantly enhances the safety of your mining operations.

- Flood Prevention: Reduces the risks of water accumulation, thereby preventing dangerous conditions.

- Stable Working Conditions: Maintains dry and stable ground, minimizing slip and fall hazards.

- Reliable Operation: Ensures consistent performance, allowing workers to operate in safer environments.

- Emergency Readiness: Equipped to handle sudden influxes of water to keep operations secure.

- Enhanced Monitoring: Advanced sensors provide real-time data for proactive safety measures.

These measures collectively contribute to a safer working environment, essential for any mining project.

You minimize not only the physical risks but also the liability costs associated with workplace incidents.

Invest in superior mine dewatering pumps to ensure that your operations run both smoothly and securely.

Increased Productivity

Boosting your mining operation’s efficiency, top-rated mine dewatering pumps are essential for increased productivity.

These pumps manage water levels, ensuring uninterrupted access to critical mining areas.

By maintaining optimal working conditions, mine dewatering pumps play a vital role in reducing downtime. Efficient water management minimizes delays, allowing for consistent output and higher overall productivity levels.

For instance, advanced sensors and automation integrated into these pumps allow for real-time monitoring and adjustments. This immediate responsiveness enables miners to stay focused on extraction activities, maximizing both time and resources. A commitment to utilizing top-tier dewatering solutions ensures your operation remains both productive and resilient.

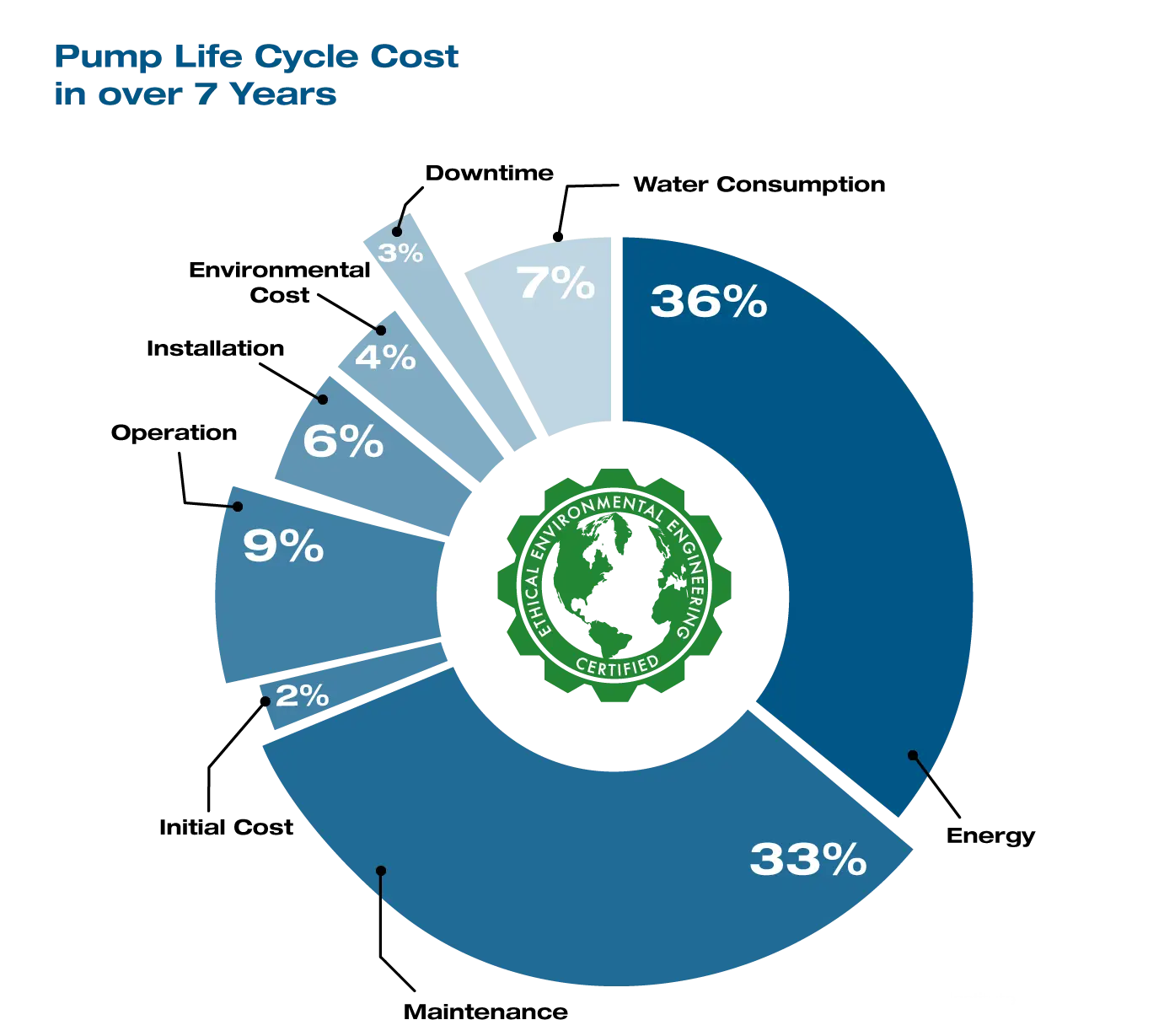

Cost Savings

Investing in high-quality mine dewatering pumps brings significant cost savings to your mining operations.

By efficiently managing water levels, these pumps reduce the need for expensive additional infrastructure. This direct reduction in infrastructure costs translates to substantial capital and operating expenditure savings.

Furthermore, top-rated mine dewatering pumps are designed for longevity and durability, lowering maintenance and replacement expenses. These pumps offer extended service lifespans, which reduces the frequency and severity of costly operational disruptions.

As an additional benefit, the improved operational efficiency of these pumps results in reduced energy consumption. This leads to lower utility bills and contributes to more sustainable, cost-effective mining practices.

In the long run, your mining operation will experience enhanced financial stability.

How to Select the Right Mine Dewatering Pump

Choosing the ideal mine dewatering pump demands a comprehensive, multi-faceted approach. Assess your mine’s specific requirements, such as water volume, depth, and contamination levels, to determine the appropriate pump capacity.

In addition, prioritize features like reliability and energy efficiency to ensure long-term operational robustness. Seeking pumps with advanced control systems can enhance functionality and adaptability in varying conditions.

Ultimately, “top-rated” and “high-performance” should be benchmarks to guide your ‘dewatering solutions’ selection process.

Capacity and Flow Rate

When considering mine dewatering pumps, understanding capacity and flow rate is imperative.

- Capacity: Refers to the total volume of water a pump can handle.

- Flow Rate: Measures the speed at which the pump can move water.

- Static Head: Indicates the vertical distance the water must be pumped.

- Total Dynamic Head (TDH): Combines static head with friction losses in the system.

- Pump Efficiency: Determines energy utilization and operational cost-effectiveness.

These factors directly influence the pump’s performance and selection.

High-capacity pumps are essential for deep mines with significant water ingress.

Ultimately, matching pump specifications to your specific mine requirements ensures operational efficacy.

Material and Design Considerations

When selecting mine dewatering pumps, material and design choices are critical to pump efficiency.

High-performance mine dewatering pumps often use a combination of durable materials and innovative designs, ensuring the longevity and reliability crucial in mining operations. Stainless steel and high-grade alloys, for instance, offer excellent resistance to corrosion and wear, essential for handling abrasive mining conditions. This reduces maintenance costs and pump downtime, maximizing operational efficiency.

Additionally, choosing a design with a robust construction ensures the pump can withstand high pressure. An optimized hydraulic design, with contoured impellers and volutes, ensures smooth fluid flow and reduces cavitation, extending pump life and enhancing performance.

Finally, integrating advanced sealing mechanisms and wear-resistant coatings can significantly reduce the risk of leakage and component degradation. These considerations are paramount to achieving consistent performance and achieving long-term cost savings, thus driving overall productivity in mining operations.

Energy Efficiency

The energy efficiency of mine dewatering pumps is critical for reducing operational costs and environmental impact.

- Variable Frequency Drives (VFDs): Enhance control and efficiency.

- Optimized Hydraulic Designs: Ensure smooth flow, reducing energy consumption.

- High-Efficiency Motors: Minimize energy usage while maximizing power output.

- Regular Maintenance Schedules: Keep pumps running at peak efficiency.

- Advanced Monitoring Systems: Allow proactive adjustments and energy conservation.

These features collectively contribute to innovative energy practices in mining operations.

Adopting these energy-efficient technologies can lead to substantial long-term savings.

Your commitment to energy efficiency can significantly improve sustainability in mining.

Maintenance Tips for Mine Dewatering Pumps

Effective maintenance is indispensable, as it ensures the optimal functioning, longevity, and reliability of mine dewatering pumps. Regularly scheduled maintenance prevents unexpected downtime, promoting consistent operational productivity and minimizing costly disruptions.

To maximize the performance of your pumps, focus on “preventive maintenance.” This involves a series of inspections and servicing designed to detect and address potential issues before they escalate. Key practices include monitoring fluid levels, checking impeller wear, and ensuring the integrity of seals and fittings. Such proactive measures can significantly extend the lifespan of your equipment.

Regular Inspections

Carry out regular inspections of your mine dewatering pumps to ensure efficiency and longevity. These inspections should be systematic and thorough, targeting both mechanical and electrical components.

They provide an opportunity to identify wear and tear. Regular checks prevent minor issues.

By conducting inspections, you can identify potential failures early. Address problems before they escalate into costly repairs or downtime. Consistent monitoring fosters reliability and operational stability, promoting safer work environments.

Ensuring a comprehensive inspection routine can greatly benefit your operations. It can significantly reduce the risk of catastrophic equipment failure and promote a proactive maintenance culture. Emphasize this practice, and the inherent reliability of your dewatering system will drastically improve, paving the way for high productivity and efficiency in your mining operations.

Cleaning Procedures

Routine cleaning is integral to maintaining the performance of mine dewatering pumps. Proper maintenance helps extend equipment lifespan.

Always disconnect the power source before cleaning. This ensures safety.

Use only recommended cleaning agents and tools. Avoid abrasive substances that can damage components or coatings.

Thoroughly clean the exterior and moving parts to remove contaminants and buildup. For optimal results, follow the manufacturer’s recommendations for cleaning frequencies and procedures. Pay special attention to “high-dirt” areas, ensuring these sections are spotless.

Troubleshooting Common Issues

Even top-rated mine dewatering pumps can encounter occasional issues, hindering their performance and potentially causing downtime.

First and foremost, if there’s a noticeable decrease in pump efficiency, check for blockages. Dirt, debris, and mineral buildup often obstruct the flow, causing the pumps to underperform. Regularly inspecting and clearing intake screens, pipes, and impellers will mitigate this issue and restore optimal functionality to your pumps.

Additionally, assess the seals and gaskets for any signs of wear and tear. These components play a crucial role in preventing leaks and maintaining pressure. If you observe any leaks, promptly replacing the damaged seals will resolve the problem and prevent further complications.

Lastly, if your pump is making unusual noises or vibrations, investigate potential mechanical failures. Misaligned shafts, worn-out bearings, or loose parts can cause such issues. Address these mechanical concerns swiftly to ensure your mine dewatering pumps operate smoothly and maintain their reliability. Regular maintenance and proactive troubleshooting will sustain peak performance and prolong the life of your equipment.

People Also Ask

How do I choose a mine dewatering pump?

Choosing the right mine dewatering pump involves several critical factors. First, determine the specific requirements of your mining operation, considering the volume and type of water that needs to be managed.

Evaluate the pump’s flow rate and head. These parameters will help you choose a pump that can handle the water efficiently within your mine’s unique layout.

Consider the construction and durability of the pump. Given the harsh mining environment, opt for materials resistant to abrasion and corrosion.

Check the pump’s energy efficiency. Selecting a pump with optimized energy consumption will reduce operational costs and enhance sustainability.

Customer support and available services from the manufacturer should also be a critical consideration, ensuring you receive timely assistance and maintenance services if needed.

Lastly, assess what other professionals in the mining industry recommend. Peer-reviewed ratings and user testimonials can offer invaluable insights into the pump’s real-world performance.

Which pump is best for dewatering?

When selecting mine dewatering pumps, you must account for various operational conditions and environmental factors.

Primarily, it’s essential to analyze the pump’s performance in terms of flow rate, head capacity, and power consumption. These elements are crucial for maintaining efficient and continuous operation under challenging mining conditions. Moreover, consider the pump’s ability to handle abrasive materials and solids to reduce downtime and maintenance costs.

Additionally, nowadays, there is a wide array of advanced dewatering pumps available. Solutions range from submersible pumps to centrifugal types, each offering specific advantages and fitting distinct scenarios. Understanding your site’s unique requirements will provide clarity on which model will deliver optimal results.

Therefore, investing in mine dewatering pumps that feature robust construction, energy-efficient designs, and strong manufacturer support is paramount. By doing so, you ensure your mining operations remain smooth, productive, and environmentally responsible, while also positioning yourself well for future challenges.

What is the most common method of mine dewatering?

The most common method of mine dewatering is pumping.

Pumping systems are extensively used across most mining operations. These systems operate by using pumps that remove water from mining zones, allowing for safer working conditions and the continuation of mining activities. Specifically, various types of mine dewatering pumps, such as submersible, centrifugal, and positive displacement pumps, are employed depending on the specific requirements of the site.

These pumps work continuously and efficiently.

The selection of a proper pump relies upon factors like the depth and volume of the water, as well as the geology of the mine.

Without dewatering pumps, managing water ingress in mines would be a formidable challenge. However, with advancements in pump technology, modern mine dewatering pumps are engineered to handle large volumes of water, possess durability under harsh conditions, and ensure minimal downtime. This not only enhances the safety and productivity of mining operations but also mitigates the environmental impact by allowing for better water management.

What types of pumps are used in mines?

In mining operations, various types of mine dewatering pumps play critical roles in effective water management and safe working conditions.

Submersible pumps, for instance, are indispensable in mining due to their ability to operate underwater, providing a robust solution for deep and flooded areas. These pumps are designed to handle a range of water volumes and pressures, adapting seamlessly to the demanding environments found in mines.

Additionally, centrifugal pumps are a prevalent choice in mines. By creating a centrifugal force, these pumps efficiently move water through pipelines, maintaining a steady discharge rate and proving their effectiveness in moderate-depth mining applications.

Lastly, positive displacement pumps are employed in scenarios requiring precise control over the flow rate. These pumps are particularly useful for handling slurries and viscous liquids, contributing to effective water and waste management within mining operations. Their reliability ensures consistent performance, safeguarding both equipment and personnel from water-related hazards.

Conclusion

Investing in top-rated mine dewatering pumps is essential for effective water management and safe working conditions.

By selecting the right pump, you ensure that your mining operations remain efficient, regardless of the challenges posed by water influx. Submersible pumps, with their exceptional depth-operating capabilities, can tackle flooded areas effortlessly, while centrifugal pumps maintain a consistent discharge suitable for moderate-depth mining.

Moreover, positive displacement pumps offer precise control, making them ideal for complex scenarios involving slurries and viscous fluids. Their inclusion in your equipment arsenal guarantees reliable performance, contributing significantly to both safety and productivity.

Implementing a well-rounded dewatering strategy with these top-rated pump options will elevate your operational standards. The advancements in these technologies not only protect your assets but also uphold your commitment to maintaining high safety and environmental standards, ensuring long-term success and sustainability in your mining endeavors.