Imagine the efficiency of a conductor orchestrating a symphony, ensuring every note achieves harmony.

Similarly, a diesel pump provides precision and reliability to efficiently manage dewatering operations.

Built for demanding conditions, these pumps excel where other technologies may falter, ensuring your projects remain on schedule.

Introduction to Diesel Pumps

Diesel pumps, including construction pumps, are essential powerhouses for dewatering applications, providing unparalleled efficiency and reliability. These pumps stand out because they deliver consistent performance even under challenging conditions.

Durable construction ensures longevity, minimizing potential downtime.

Engineered to handle various dewatering needs, diesel pumps offer robust solutions for both small and large projects. They are meticulously designed to deliver high flow rates and tackle significant water volumes effortlessly.

Incorporating a diesel pump for your dewatering project means investing in a proven, time-tested technology. It ensures you have a dependable resource ready to address any water-related challenges that arise, making your operations smoother and more efficient.

Understanding Diesel Pumps

Diesel pumps are essential for various applications, including water pumping, dewatering, and more. These pumps are known for their durability, efficiency, and ability to handle challenging environments. When choosing a diesel pump, it’s crucial to consider the type of pump, its capacity, and the specific requirements of your project.

Types of Diesel Pumps

Diesel pumps for dewatering come in two main categories: non-submersible and submersible. Understanding these categories’ distinctions can optimize your selection process and operational efficiency.

Non-submersible diesel pumps are typically used in situations where the pump needs to be positioned above the water level, making it easier to access for maintenance. They are ideal for large-scale projects requiring high flow rates and substantial suction power.

On the other hand, submersible diesel pumps are designed to operate while fully submerged, providing versatility and reliability in challenging environments.

There are several types of diesel pumps available, each designed for different applications:

- Self-Priming Pumps: These pumps are ideal for applications where the pump needs to be primed automatically. They are commonly used in construction and dewatering projects.

- Centrifugal Pumps: Known for their high efficiency and ability to handle large volumes of water, centrifugal pumps are perfect for irrigation and large-scale water pumping tasks.

- Diaphragm Pumps: These pumps are suitable for handling abrasive and viscous fluids, making them ideal for mining and industrial applications.

Low Head, Medium Head, and High-Head Diesel Pumps

Careful selection of diesel pumps according to the head level is crucial for optimizing dewatering processes. Low head, medium head, and high-head pumps each serve distinct functions.

Low-head diesel pumps excel in applications that require transferring water over short distances. These pumps are perfect for draining basements, flooded areas, or small construction sites with minimal elevation changes.

High-head diesel pumps can handle substantial elevation differences, making them indispensable for challenging dewatering projects.

Medium-head diesel pumps bridge the gap, offering versatility for a variety of projects, including irrigation and mid-level construction. They deliver reliable performance without the excess power required for high-head applications, ensuring efficiency and cost-effectiveness. Each type requires careful consideration to ensure optimal performance for your specific needs.

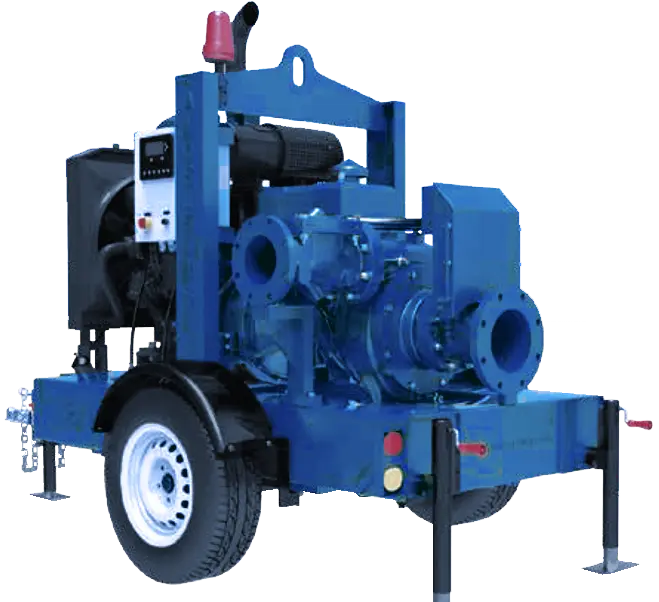

Trailor Mounted Diesel Pumps

Trailer mounted diesel pumps offer unmatched mobility, enabling you to address water management issues efficiently and effectively.

When selecting a diesel pump, the portability of a trailer mounted solution provides the added benefit of ease in transportation. Whether you’re managing water on a construction site or tackling flooding emergencies, these pumps simplify logistics and reduce downtime.

Specifically, trailer mounted diesel pumps are designed to withstand rugged environments. You’ll find that their robust construction and powerful engines are tailored to handle the most demanding dewatering tasks efficiently and reliably.

Moreover, these pumps come equipped with features such as automatic priming and high fuel efficiency, ensuring continuous operation with minimal intervention. Elevate your dewatering efforts with a trailer mounted diesel pump that combines durability, performance, and convenience, making it an essential asset for any advanced water management scenario.

Skid Mounted Diesel Pumps

Skid mounted diesel pumps offer remarkable stability.

These pumps are meticulously designed to remain firmly in place, even under challenging conditions. You can rely on skid mounted systems for extensive dewatering operations at fixed locations, such as mining sites, construction zones, and municipal water works. Furthermore, their robust frame and secure anchoring ensure minimal vibration and maximum efficiency.

Explore skid mounted options.

You’ll realize that skid mounted diesel pumps boast superior reliability and are less prone to displacement. They are an ideal choice for semi-permanent setups where consistent high performance is paramount.

In addition, skid mounted diesel pumps incorporate advanced technological features. This includes enhanced fuel systems and automated controls, allowing you to monitor and manage your operations with precision. Their rugged design and cutting-edge capabilities make them invaluable for intensive dewatering applications.

Achieve unparalleled results by integrating skid mounted diesel pumps into your water management strategy. With a focus on durability and outstanding performance, these pumps will undeniably support your projects’ success, ensuring continuous operational efficiency even in the most demanding environments.

Single VS Multistage Pumps

Choosing between single and multistage pumps depends on your specific application requirements and operational conditions. Both types offer distinct advantages and limitations.

- Single-stage Pumps: These pumps have one impeller and are perfect for low to medium head applications, providing simplicity and ease of maintenance.

- Multistage Pumps: Consisting of multiple impellers, these pumps can handle high head requirements, making them suitable for applications involving significant pressure.

Single-stage pumps are typically more cost-effective and have a straightforward design, ideal for less complex tasks.

Conversely, multistage pumps, though more intricate, offer superior efficiency and performance for demanding scenarios requiring higher pressure capabilities.

Key Features of Diesel Pumps

Reliability, exceptional longevity, and robust construction make diesel pumps the cornerstone of critical dewatering tasks.

In addition, these pumps offer superior fuel efficiency and versatile operational capacities, enhancing their popularity for applications ranging from construction sites to flood relief efforts.

The terms “fuel-efficient” and “high-powered” often underscore the performance attributes of these essential dewatering tools.

Efficiency and Performance

When it comes to precision engineering, diesel pumps excel in delivering unmatched efficiency and performance for dewatering applications.

- Fuel Efficiency: Superior fuel consumption rates ensure longer operation times and reduced refueling frequency.

- High Flow Rates: Capable of handling significant volumes of water, enhancing productivity on large-scale projects.

- Reliability: Engineered for consistent performance, minimizing downtime and maintenance requirements.

- Durability: Robust construction ensures longevity even in harsh operating conditions.

Equipped with advanced design features, these pumps optimize resource utilization, thereby minimizing operational costs.

By integrating state-of-the-art technologies, diesel pumps provide unparalleled efficiency, setting new standards in performance and reliability.

Durability and Build Quality

When you invest in a diesel pump, you prioritize unrivaled durability and exceptional build quality.

These pumps are engineered to withstand demanding operational conditions, ensuring your project progresses smoothly even in the toughest environments. Designed and built with meticulous attention to detail, diesel pumps incorporate high-quality materials and advanced manufacturing techniques.

Furthermore, stringent quality control measures during production guarantee that every unit performs up to the highest standards. This results in extended service life, reducing the need for frequent replacements or repairs, thus optimizing your investment.

Because reliability is paramount, diesel pumps are subject to rigorous testing, ensuring they function flawlessly under pressure. Their resilient structures and robust components are crafted to endure the rigors of intense dewatering tasks, offering peace of mind.

Count on your diesel pump to deliver sustained, high-performance output, ensuring operational efficiency.

Benefits of Using Diesel Pumps

Choosing a diesel pump for dewatering not only presents a cost-effective solution but also guarantees exceptional operational efficiency. Diesel engines are renowned for their fuel efficiency, enabling longer run times between refuels. Additionally, diesel pumps offer superior power output, effectively handling even the most strenuous dewatering tasks with ease, making them ideal for high-demand projects in remote areas where electric power sources may be unavailable. Their robust design and exceptional durability also translate to lower maintenance costs and reduced downtime, ensuring that your dewatering operations remain uninterrupted and highly efficient.

Fuel Efficiency

Ensuring fuel efficiency in your dewatering operations translates to significant cost savings and improved productivity.

- Superior Fuel Economy: Diesel pumps maximize energy usage.

- Longer Run Time: Less frequent refueling enhances continuous operation.

- Reduced Fuel Costs: High-efficiency engines decrease total fuel consumption.

- Environmental Impact: Emissions are minimized due to better combustion efficiency.

By investing in a high-efficiency diesel pump, you enable more sustainable operations.

Operational reliability is enhanced as less time and resources are spent on refueling tasks.

Cost-Effective Operation

Leveraging a diesel pump for dewatering ensures robust performance, lower operational costs, and maximized efficiency. Its efficiency and durability provide unmatched value for your investment.

Cost-effective operation requires minimizing the frequency of major maintenance tasks. Diesel pumps are engineered to deliver this through superior durability.

Furthermore, innovative designs in modern diesel pumps include self-priming features (greatly reducing prepping time). This translates to increased productivity.

Their longevity and ability to handle rigorous operational demands mean fewer replacements. Long-term cost efficiency thus becomes attainable.

These pumps offer substantial savings by automating many dewatering tasks, allowing you to allocate manpower elsewhere. This optimizes workflow and reduces overall labor costs.

Ultimately, your choice of a diesel pump isn’t just about immediate costs. Strategic operational planning ensures a significant return on investment through reliable, long-term performance.

Choosing the Right Diesel Pump

Selecting the right diesel pump requires in-depth knowledge and careful consideration of your specific dewatering needs.

To begin with, evaluate the pump’s capacity and maximum flow rate, ensuring they align with the demands of your project. Next, assess the fuel efficiency, as well-designed diesel pumps maximize operational time and minimize costs.

Finally, consider the pump’s ease of maintenance and any advanced features that enhance performance, such as automatic shutdown to prevent damage.

Assessing Your Needs

Properly assessing your needs is crucial for choosing the right diesel pump for dewatering projects.

- Project Size and Scope: Determine the scale of dewatering required.

- Water Type: Evaluate whether the water contains debris or chemicals.

- Flow Rate Needs: Calculate the necessary flow rate for efficient operation.

- Operational Environment: Consider the operating conditions and site accessibility.

Understanding these factors will streamline your selection process.

By honing in on these specifics, you can ensure the longevity and effectiveness of your diesel pump investment.

Key Selection Criteria

Choosing the right diesel pump is paramount for effective dewatering operations in various environments.

First, examine the power output to ensure it matches the project’s requirements.

Next, evaluate the durability and build quality, particularly if the pump will operate in harsh conditions. Robust construction ensures longevity, and reliable performance minimizes downtime and replacement costs.

Ease of mobility and installation can also be critical, especially for projects requiring frequent relocation. Look for built-in handles or wheeled frames to facilitate transportation. By prioritizing these criteria, you can select a pump that offers optimal performance, cost-efficiency, and reliability.

When selecting a diesel pump, consider the following factors:

1. Flow Rate and Pressure

The flow rate and pressure of the pump are critical factors to consider. Ensure the pump can handle the required volume of water and provide the necessary pressure for your application.

2. Fuel Efficiency

Diesel pumps are known for their fuel efficiency. However, it’s essential to choose a pump that offers the best fuel economy to reduce operational costs.

3. Durability and Maintenance

Look for pumps that are built to withstand harsh conditions and require minimal maintenance. Brands like Godwin Pumps and Pioneer Pump are known for their robust construction and reliability.

4. Portability

For projects that require mobility, consider a mobile dewatering pump. These pumps are designed for easy transportation and setup, making them ideal for construction and underground dewatering projects.

5. Rental Options

If you need a pump for a short-term project, consider pump rental options. Many distributors offer a range of rental solutions to meet your needs.

Popular Brands

Several reputable brands offer high-quality diesel pumps:

- Godwin Pumps: Known for their reliability and performance, Godwin Pumps are a popular choice for dewatering and construction applications. The Xylem Godwin series offers advanced features and robust construction.

- Pioneer Pump: Pioneer dewatering pumps are renowned for their efficiency and durability. They are ideal for a wide range of applications, including water pumping and dewatering.

- Dynapro Pumps: When it comes to dewatering solutions, Dynapro Pumps stands out as a leading provider of high-quality, reliable equipment. Their range of dewatering pumps is designed to meet the diverse needs of industries such as construction, mining, and municipal services. Here’s an in-depth look at Dynapro Pumps’ dewatering options and why they might be the perfect choice for your project.

Dynapro Pumps Dewatering Solutions

1. Self-Priming Pumps

Dynapro’s self-priming pumps are engineered for efficiency and ease of use. These pumps are ideal for applications where automatic priming is essential, such as construction sites and emergency dewatering. The self-priming feature ensures that the pump can start and operate without manual intervention, saving you time and effort.

2. Centrifugal Pumps

For large-scale water pumping tasks, Dynapro offers a range of centrifugal pumps. These pumps are known for their high efficiency and ability to handle significant volumes of water. They are perfect for irrigation, flood control, and other applications requiring robust performance and reliability.

3. Submersible Pumps

For underwater dewatering tasks, Dynapro’s submersible pumps are an excellent choice. These pumps are designed to operate while fully submerged, making them ideal for applications such as underground dewatering and sump pumping. Their rugged construction ensures durability and long-term reliability.

Key Features of Dynapro Dewatering Pumps

Durability and Reliability

Dynapro Pumps are built to last, with robust construction and high-quality materials. This durability ensures that the pumps can withstand the rigors of demanding environments, providing reliable performance over the long term.

Fuel Efficiency

Efficiency is a hallmark of Dynapro Pumps. Their dewatering pumps are designed to maximize fuel economy, reducing operational costs and minimizing environmental impact. This makes them a cost-effective choice for any dewatering project.

Ease of Maintenance

Maintenance is a critical factor in the longevity and performance of dewatering equipment. Dynapro Pumps are designed for easy maintenance, with accessible components and straightforward servicing procedures. This reduces downtime and keeps your operations running smoothly.

Portability

For projects that require mobility, Dynapro offers portable dewatering pumps. These pumps are easy to transport and set up, making them ideal for temporary sites and emergency situations. Their compact design ensures they can be deployed quickly and efficiently.

Applications of Dynapro Dewatering Pumps

Construction

In construction, dewatering is essential for creating dry, stable work environments. Dynapro’s pumps are perfect for removing groundwater and surface water, ensuring that construction sites remain safe and operational.

Mining

Mining operations often require robust dewatering solutions to manage water ingress and maintain safe working conditions. Dynapro’s submersible and centrifugal pumps are well-suited for these challenging environments, providing reliable performance and durability.

Municipal Services

Municipalities rely on efficient dewatering solutions for flood control, wastewater management, and infrastructure maintenance. Dynapro’s range of pumps offers the versatility and reliability needed to meet these demands.

Dynapro Pumps offers a comprehensive range of dewatering solutions designed to meet the needs of various industries. With options including self-priming, centrifugal, and submersible pumps, Dynapro ensures that you have the right equipment for your specific application. Their focus on durability, fuel efficiency, ease of maintenance, and portability makes them a top choice for any dewatering project. Invest in Dynapro Pumps to ensure your dewatering operations are efficient, reliable, and cost-effective.

Installation and Maintenance

Proper installation of your diesel pump is essential for maximizing efficiency and prolonging its lifespan. Ensure the site is well-prepared, with a stable surface, and that all connections are secure. This foundational step minimizes operational risks and optimizes the pump’s performance.

Regular maintenance, including routine checks, cleaning, and timely part replacements, is crucial for ensuring the longevity and effectiveness of your diesel pump.

Step-by-Step Installation Guide

To successfully install your diesel pump, proper preparation and systematic execution are crucial.

- Select the Site: Ensure a stable, level surface to set up your pump.

- Prepare the Connections: Secure both the inlet and outlet hoses firmly to avoid leakages.

- Fuel and Oil: Fill the pump with the recommended diesel and oil types.

- Prime the Pump: Follow the manufacturer’s instructions to prime the pump.

- Initial Testing: Start the pump to check for any operational issues.

Careful adherence to these steps will ensure a smooth installation process.

By diligently following this guide, you can minimize risks and maximize the pump’s efficiency.

Routine Maintenance Tips

Regular maintenance of your diesel pump is indispensable for optimal performance and longevity.

First, check the fuel and oil levels before each use. Doing so prevents unexpected breakdowns.

Clean all filters frequently to ensure the pump operates without blockages or reduced efficiency.

Inspect hoses and connections regularly for leaks or wear to prevent operational interruptions. Replace any damaged parts promptly.

Keep detailed maintenance records. This practice helps you track service intervals and anticipate future needs.

Applications of Diesel Pumps

Diesel pumps, particularly those designed for dewatering tasks, serve a diverse range of applications.

In construction, these pumps are indispensable during excavation (dewatering) to keep work sites dry, allowing for seamless project progression and safety.

The terms “dewatering” and “dewatering pump” often become synonymous in discussions about these crucial applications.

Mining

Diesel pumps are crucial in mining.

In such a demanding environment, water buildup can halt operations. Diesel pumps effectively address this by offering powerful dewatering capabilities essential for keeping mining sites operational. Furthermore, these pumps can endure the harsh conditions and extended use typical in mining.

Ensuring reliability is paramount.

You must select and maintain high-quality diesel pumps to avoid costly downtime. Their robust construction and fuel efficiency contribute to continuous operation in remote or underground mines.

Utilize advanced dewatering strategies by incorporating diesel pumps into your mining operations. These pumps play a pivotal role in maintaining productivity and safety, ensuring that you meet project timelines and production targets. Their superior performance can make a significant difference in the hostile conditions of modern mining.

Agriculture and Irrigation

Diesel pumps for dewatering are indispensable for agriculture, particularly in irrigation practices and water management.

They offer reliability and power in areas with limited electrical access.

Using a diesel pump, you can efficiently manage water resources, supporting the health of your crops and enhancing yield. The durability of diesel pumps ensures they perform consistently across different terrains and weather conditions, essential for uninterrupted farming activities.

Their portable nature also empowers you to address various irrigation needs, from watering extensive farmlands to assisting in emergencies such as flooding. By investing in a diesel pump, you not only improve water distribution but also contribute to the sustainability and resilience of your agricultural operations.

Industrial Uses

Diesel pumps are pivotal across various industrial applications, ensuring efficient dewatering processes and enhanced operational productivity.

- Construction Sites: Maintaining dry foundations and work areas.

- Mining Operations: Extracting water from mining pits.

- Municipal Services: Addressing flood control and sewage management.

- Manufacturing Plants: Handling waste water and spill management.

These robust pumps stand out for their high reliability and capability to operate under tough conditions. They ensure minimal downtime and consistent performance.

Adopting diesel pumps can lead to substantial energy savings and operational cost reduction, vital for profit margins.

Construction Projects

In the realm of construction, a reliable diesel pump is essential for effective dewatering operations.

Your projects demand the maintenance of dry foundations.

Utilizing these pumps can prevent water accumulation, ensuring safety and structural integrity at your sites. Robust and durable, diesel pumps excel in challenging environments, remaining operational even under heavy workloads.

Moreover, investing in diesel pumps greatly minimizes potential delays and costly disruptions to your project timeline. As a result, you safeguard both your budget and the overall quality of the construction. Your ability to maintain a seamless workflow with efficient dewatering solutions underscores your commitment to excellence and innovation in the construction industry.

Troubleshooting Common Issues

Should your diesel pump exhibit performance inconsistencies, a variety of troubleshooting methodologies, tailored to pinpoint specific causes, will be essential. Frequent symptoms like reduced flow rates, unusual noises, or visible leaks necessitate a methodical inspection plan targeting components such as the impeller, seals, and fuel system. By addressing these issues promptly, you maintain the operational integrity and longevity of your dewatering equipment.

Identifying Problems

In your quest for operational excellence, identifying problems early is critical to maintain peak efficiency and performance.

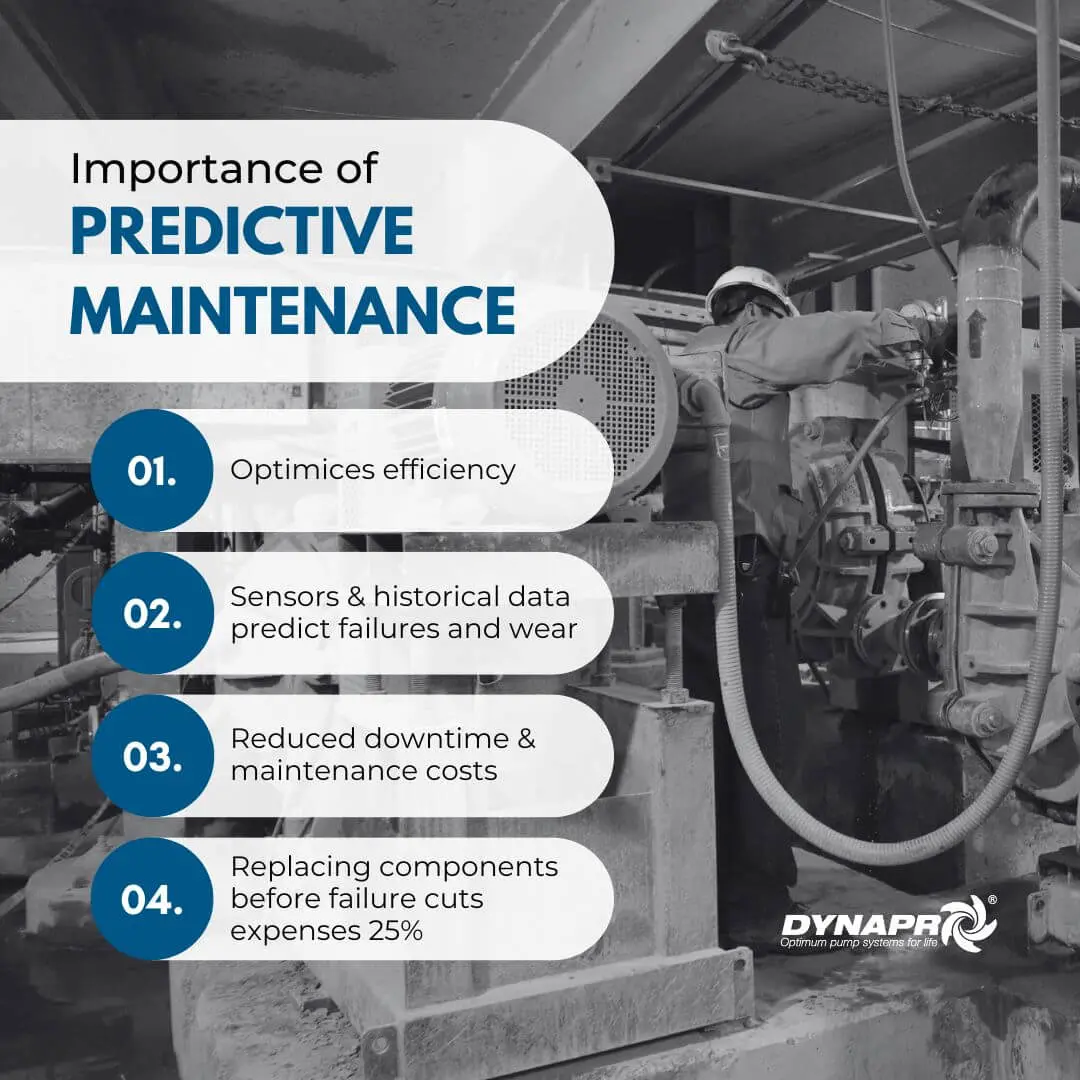

First and foremost, you must stay vigilant for early warning signs such as inconsistent pumping rates or unusual vibrations. These symptoms can often indicate underlying mechanical issues such as impeller wear, seal degradation, or fuel system inefficiencies. Recognizing these signs promptly enables you to take corrective measures before minor problems become costly repairs.

Additionally, regular inspections are fundamental to a proactive maintenance strategy. By systematically examining components like hoses, valves, and connections, you ensure that your diesel pump operates without unexpected interruptions. This thorough approach can significantly minimize downtime and extend the lifespan of your equipment.

Finally, leveraging advanced diagnostic tools can streamline your problem-identification process. By utilizing technologies such as vibration analysis and thermal imaging, you can detect anomalies with high precision, bolstering your ability to address potential failures preemptively. This forward-thinking approach not only saves time and resources but also cements your reputation as a leader in construction excellence.

Quick Fixes and Solutions

Immediate action can safeguard equipment functionality.

When your diesel pump shows irregular performance, start with a basic inspection. First, ensure there are no visible obstructions or damaged components. Tighten any loose bolts, clean clogged filters, and verify that all hoses and connections are secure. Sometimes, these quick adjustments can resolve minor issues, restoring your pump’s efficiency.

Check the fuel for contamination.

Next, use calibration to address flow inconsistencies. Proper calibration ensures the pump operates at optimal levels, preventing both overuse and inefficiency. Always refer to manufacturer guidelines for specific calibration procedures.

Establish a consistent log for recording performance metrics. Detailed records can help you identify patterns and predict when quick fixes might be necessary, thus ensuring uninterrupted operations. Adopting these practices demonstrates your commitment to maintaining operational excellence without significant downtime.

Conclusion and Next Steps

Your focus on maintaining diesel pump efficiency can significantly impact operational success and sustainability.

Regular inspections and timely maintenance are pivotal.

They not only prolong the lifespan of your equipment but also ensure consistent performance, which is critical in dewatering applications.

By adhering to these strategies and seeking continual improvement, you position yourself for long-term achievement and resilience in your field. Make it a priority to review the latest best practices, invest in proper training, and adopt new technologies to maintain your competitive edge.

When it comes to purchasing a diesel pump, there are several key factors to consider to ensure you select the right equipment for your needs. Whether you’re involved in construction, mining, or agriculture, understanding these considerations will help you make an informed decision.