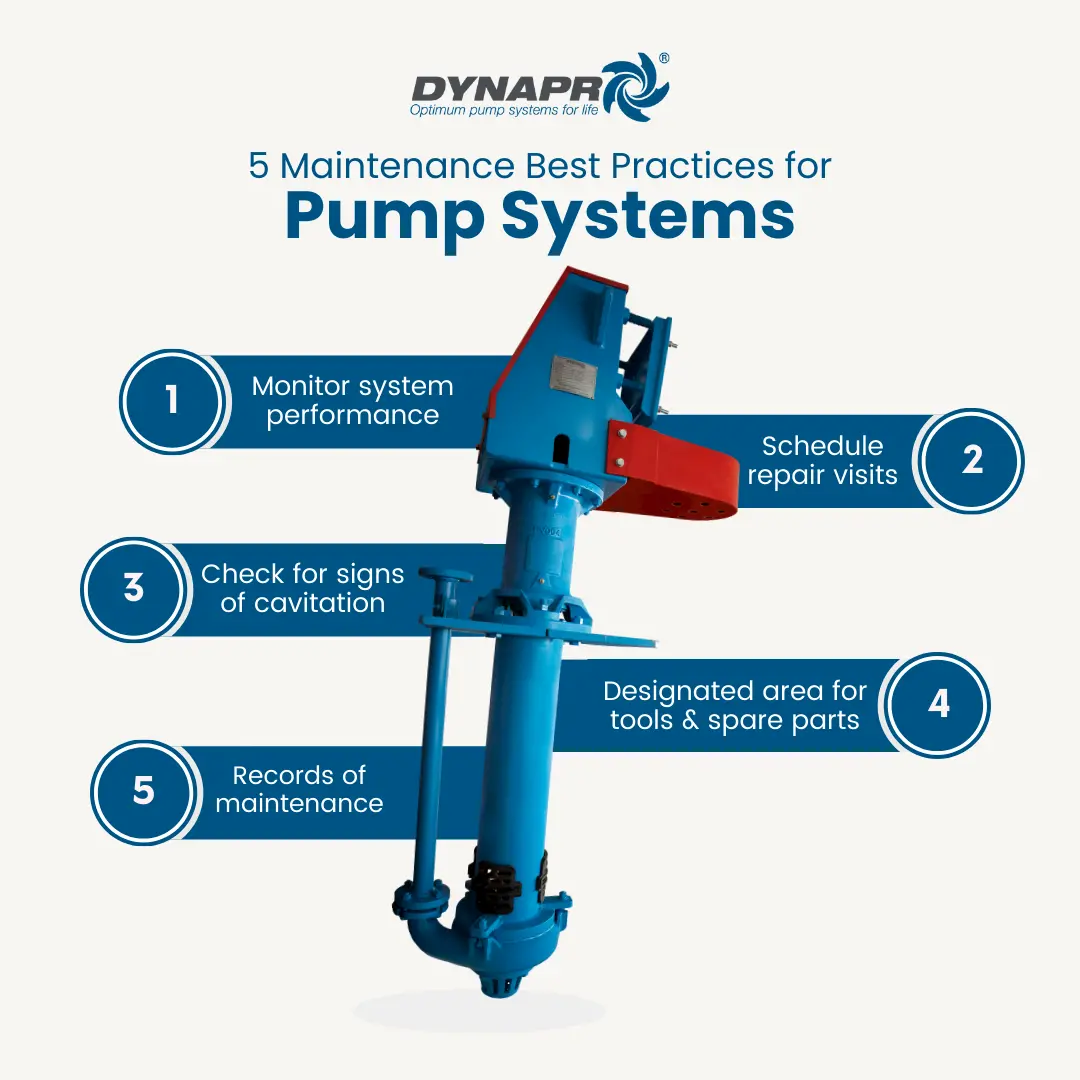

Prolonging Pump Life: Essential Maintenance Practices

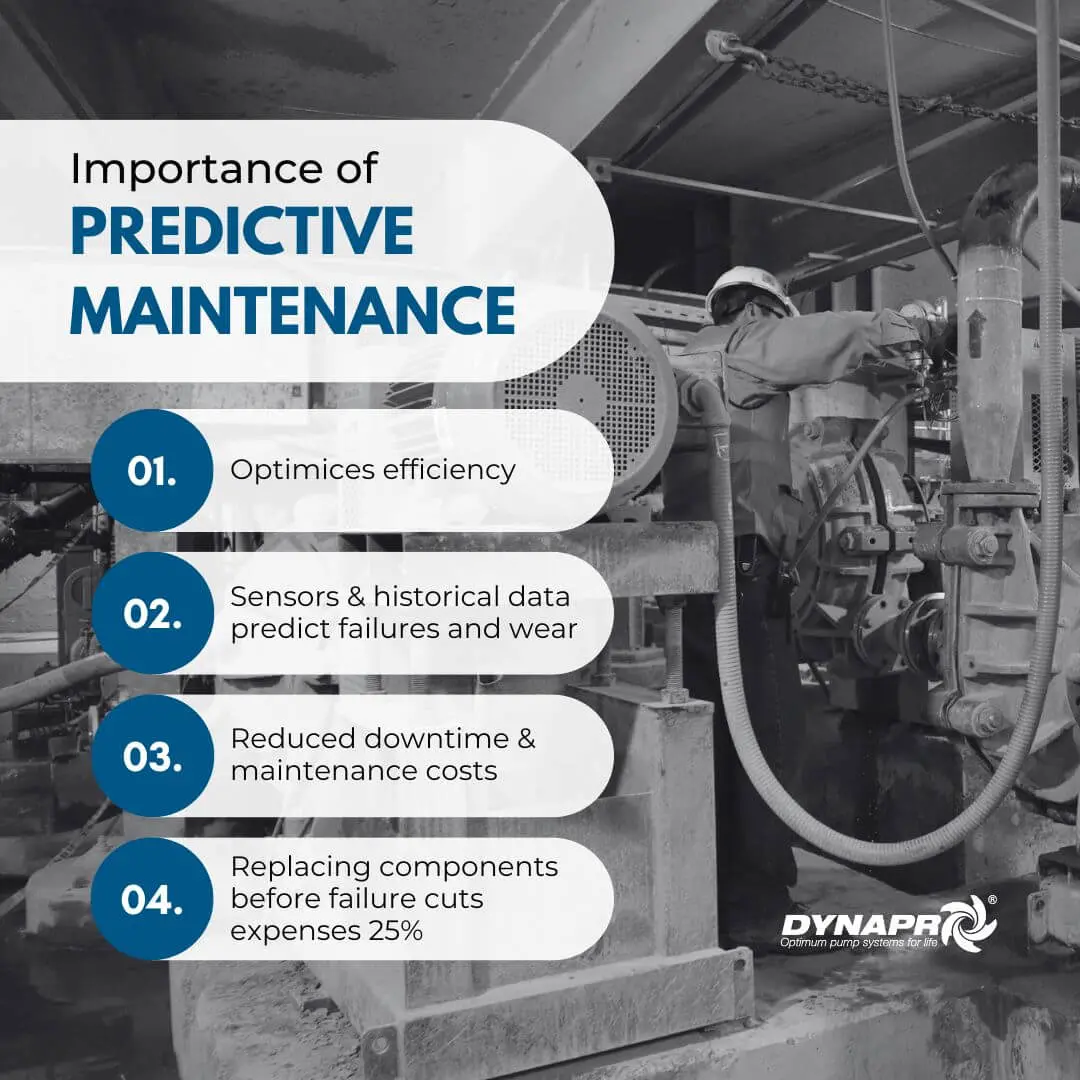

To ensure your dewatering pumps operate efficiently and have a prolonged lifespan, it’s crucial to adhere to essential maintenance practices. Regular maintenance not only prevents unexpected breakdowns but also enhances the overall performance of your equipment. Implementing a structured maintenance schedule, including daily inspections, effective cleaning, and proper lubrication, can significantly reduce wear and tear. Additionally, seasonal maintenance checks help in identifying potential issues before they escalate, ensuring your pumps are always ready for operation.

Understanding Dewatering Pumps: Types and Applications

Dewatering pumps are vital in various industries, including construction, mining, and wastewater management, where efficient water removal is crucial. These pumps are designed to remove water from a specific area, making them essential for projects that require dry conditions. There are several types of dewatering pumps, each suited for different applications. Centrifugal pumps are ideal for high-flow, low-pressure applications, while submersible pumps are perfect for underwater operations. Understanding the specific needs of your project will help you choose the right pump, ensuring optimal performance and efficiency.

Dewatering Applications in Mining

Dewatering is a critical process in the mining industry, essential for maintaining safe and efficient operations. Mining sites often encounter significant water accumulation due to groundwater inflow, precipitation, and the mining process itself. Effective dewatering ensures that mining activities can proceed without interruption, safeguarding both equipment and personnel.

In open-pit mining, dewatering pumps are used to remove water from the pit, preventing flooding and allowing for continuous excavation, ensuring effective water removal in challenging conditions. Submersible pumps are commonly employed in these scenarios due to their ability to operate underwater and handle large volumes of water. Additionally, centrifugal pumps are utilized to transport water away from the site, ensuring that the pit remains dry.

Underground mining operations also rely heavily on dewatering pumps to manage water ingress. Water can seep into underground tunnels and shafts, posing a risk to miners and equipment. High-capacity submersible pumps are often deployed to remove water from these confined spaces, maintaining a safe working environment. In some cases, specialized pumps are used to handle slurry and other abrasive materials commonly found in mining operations.

Tailings management is another crucial area where dewatering pumps play a vital role. Tailings, the byproducts of mining processes, are often stored in large ponds. Dewatering these tailings helps in reducing the volume of waste, facilitating easier handling and disposal. This process also aids in the recovery of water, which can be reused in mining operations, promoting sustainability.

Overall, dewatering pumps are indispensable in the mining industry, ensuring that operations run smoothly and safely by providing reliable water removal solutions. By effectively managing water levels, these pumps help in minimizing downtime, reducing operational costs, and enhancing productivity. Investing in high-quality dewatering pumps tailored to the specific needs of mining applications is essential for achieving optimal performance and efficiency.

Daily Inspection Routines to Prevent Wear and Tear

Daily inspections are a cornerstone of effective dewatering pump maintenance. Start by checking for any visible signs of wear and tear, such as cracks or leaks. Ensure that all connections are secure and that there are no obstructions in the pump’s intake and discharge areas. Monitor the pump’s performance, listening for any unusual noises that could indicate a problem. Regularly inspect the oil levels and look for any signs of contamination. By conducting these daily checks, you can catch minor issues before they develop into major problems, thereby extending the life of your pump.

Daily Inspection Checklist for Dewatering Pumps

- Visual Inspection

- Check for visible signs of wear and tear, such as cracks, leaks, or corrosion.

- Ensure all connections and fittings are secure and free from damage.

- Inspect the pump housing and mounting for any abnormalities.

- Performance Monitoring2. Listen for unusual noises that could indicate mechanical issues.2. Observe the pump’s operation to ensure it is running smoothly and efficiently.2. Check for any vibrations that may suggest misalignment or imbalance.

- Intake and Discharge Areas3. Inspect the intake and discharge ports for obstructions or debris.3. Ensure that screens and filters are clean and intact.3. Verify that hoses and pipes are free from kinks, cracks, or blockages.

- Lubrication Check4. Check oil levels and top up if necessary, following the manufacturer’s guidelines.4. Inspect for any signs of oil contamination or leaks.4. Ensure that all moving parts, such as bearings and seals, are adequately lubricated.

- Electrical Components5. Inspect electrical connections for signs of wear, corrosion, or loose wires.5. Check the condition of power cables and ensure they are properly insulated.5. Test the functionality of control panels and switches.

- Pump Operation6. Verify that the pump is primed and operating at the correct pressure and flow rate.6. Monitor the pump’s temperature to prevent overheating.6. Ensure that the pump is cycling on and off correctly, without short cycling.

- Safety Checks7. Confirm that all safety guards and covers are in place and secure.7. Ensure that emergency shutoff switches are accessible and functional.7. Check for any potential hazards around the pump area, such as spills or obstructions.

- Documentation8. Record any findings, including issues identified and actions taken.8. Note the pump’s operating hours and any maintenance performed.8. Keep a log of daily inspections to track the pump’s condition over time.

By following this daily inspection checklist, you can proactively identify and address potential issues, ensuring the reliable and efficient operation of your dewatering pumps.

Effective Cleaning Techniques for Dewatering Pumps

Keeping your dewatering pumps clean is essential for maintaining their efficiency and longevity. Begin by flushing the pump with clean water to remove any debris or sediment. Use a soft brush to clean the exterior surfaces, paying special attention to the intake and discharge ports. For submersible pumps, ensure that the impeller and volute are free from obstructions. Avoid using harsh chemicals that could damage the pump’s components. Regular cleaning prevents buildup that can hinder performance and cause premature wear.

Lubrication Best Practices to Enhance Pump Longevity

Proper lubrication is critical for the smooth operation of dewatering pumps. Use high-quality lubricants recommended by the pump manufacturer. Regularly check the lubrication levels and top up as necessary. Ensure that all moving parts, such as bearings and seals, are adequately lubricated to minimize friction and prevent overheating. Over-lubrication can be just as harmful as under-lubrication, so follow the manufacturer’s guidelines closely. Consistent lubrication reduces wear and tear, enhancing the pump’s longevity and reliability.

Seasonal Maintenance Checklist: Keeping Pumps Ready Year-Round

Seasonal maintenance is essential for keeping your dewatering pumps in top condition throughout the year. In the spring, inspect the pump for any damage that may have occurred during the winter months. Clean and lubricate all components, and replace any worn parts. During the summer, ensure that the pump is not overheating and that it is operating efficiently. In the fall, prepare the pump for winter by draining any remaining water and protecting it from freezing temperatures. Regularly update your maintenance checklist to address any specific needs based on the season and operating conditions.

Troubleshooting Common Issues with Dewatering Pumps

Even with regular maintenance, dewatering pumps can encounter issues that require troubleshooting. Common problems include reduced flow rate, unusual noises, and overheating. If you notice a reduced flow rate, check for blockages in the intake or discharge lines. Unusual noises may indicate a problem with the impeller or bearings, requiring immediate attention. Overheating can be caused by insufficient lubrication or excessive load on the pump. By systematically identifying and addressing these issues, you can ensure that your dewatering pump continues to operate efficiently.

Troubleshooting Checklist for Dewatering Pumps

| Symptom | Inspect | Look for |

|---|---|---|

| Reduced flow rate or pressure | Intake and discharge lines | Blockages, obstructions, or leaks |

| Impeller | Wear, damage, or debris buildup | |

| Pump seals | Leaks or wear | |

| Unusual noises | Bearings | Wear, lack of lubrication, or damage |

| Impeller | Misalignment, damage, or debris | |

| Motor | Electrical issues or mechanical faults | |

| Overheating | Lubrication levels | Insufficient lubrication or contamination |

| Cooling system (if applicable) | Blockages or malfunction | |

| Operating conditions | Overloading or running beyond capacity | |

| Electrical issues | Power supply | Loose connections, blown fuses, or tripped breakers |

| Control panel | Faulty switches or indicators | |

| Motor | Electrical faults or overheating | |

| Leakage | Seals and gaskets | Wear, damage, or improper installation |

| Housing and casing | Cracks or corrosion | |

| Connections and fittings | Loose or damaged components | |

| Vibration | Mounting and alignment | Loose bolts or misalignment |

| Impeller | Imbalance or damage | |

| Bearings | Wear or lack of lubrication | |

| Priming issues | Suction line | Air leaks or blockages |

| Foot valve or check valve | Malfunction or debris | |

| Priming mechanism | Faulty operation or damage | |

| Operational inconsistencies | Control system | Faulty sensors or controllers |

| Power supply | Voltage fluctuations or interruptions | |

| Pump components | Wear, damage, or improper settings |

By systematically inspecting these parts and looking for the specified issues, you can effectively troubleshoot and resolve common problems with your dewatering pumps, ensuring they operate reliably and efficiently.

Prime-Flow Vacuum Assisted Dry Prime Pump Packages

Prime-Flow vacuum-assisted dry prime pump packages from Dynapro Pumps offer a reliable solution for all your dewatering applications. With over 40 years of experience, we specialize in providing high-performance and efficient pumps that excel even in the most challenging conditions. Our vacuum-assisted priming system ensures quick and easy startup, reducing downtime and boosting productivity. Built with robust construction and advanced features, Prime-Flow pumps are designed to handle the toughest dewatering tasks, ensuring you have a dependable and efficient solution for all your needs.

Product Details

Meeting the highest standards, find out more about what makes our pumps different!

Pump Selection Charts

Find the right pump for your application, whether it’s low, medium, or high-head.

Request a Quote

A technical specialist can assist you in your selection and provide the best performing option for your project.

The Excellence of Our Prime-Flow Pumps

Dynapro sets the gold standard with our advanced Prime-Flow Pumps. We offer hot galvanizing for all canopy steel structure components, including the base, fuel tank, panels, and roofs, and provide the option to hot galvanize all skids and trailers upon request.

A standout feature of our Prime-Flow Pumps is the modular design of the canopies. This innovative approach allows for easy disassembly, so if part of the canopy is damaged, you can replace only the affected section rather than the entire canopy. This advantage is particularly beneficial in today’s highly competitive market.

Our sound-attenuated pumps are engineered for convenience, featuring forklift ports on all four sides. This design gives our customers greater flexibility during loading and unloading. Additionally, the pumps are stackable, optimizing storage space and allowing for more efficient warehouse management.

We are committed to using the most advanced and environmentally friendly engines available. Every canopy design is rigorously reviewed and approved by the engine manufacturers before integration, ensuring the highest standards of quality and performance.

What are the hazards of dewatering pumps?

Dewatering pumps, while essential for many industrial and construction operations, come with various hazards that demand your attention and adherence to safety protocols.

One of the most significant risks is electrical hazards, especially given that many dewatering pumps operate in wet environments. Electric shock can occur if the pump is not properly insulated or grounded. Additionally, worn-out cables or faulty connections can exacerbate this risk.

There is also the danger of mechanical failure. Over time, wear and tear on pump components can lead to breakdowns. Regular maintenance is crucial to avoid catastrophic mechanical issues that could pose safety risks to operators and surrounding infrastructure.

Another hazard to consider is the potential for chemical exposure, particularly if the dewatering process involves contaminated water. Protective gear and proper handling protocols are necessary to mitigate this risk and ensure the safety of all personnel.

Lastly, you must be vigilant about environmental impacts. Improperly managed dewatering can lead to soil erosion, water contamination, and habitat disruption. Implementing best practices and adhering to environmental guidelines will help you minimize such adverse effects, ensuring both operational success and ecological responsibility.