Have you ever wondered what makes a dewatering pump truly exceptional? What sets apart a good pump from a great one?

Dynapro’s innovative technology.

Our Prime-Flow Pumps redefine industry standards with their superior design and unparalleled efficiency, ensuring they discharge water efficiently and your operations run smoothly and effectively.

1. Introduction to Dewatering Pumps

When tackling projects that involve water removal, dewatering pumps are indispensable tools. They efficiently extract water from various settings.

These pumps are crucial in construction, particularly for excavation sites, as well as in mining and flood control.

Moreover, dewatering pumps help prevent erosion and sedimentation, safeguarding infrastructure.

Understanding how dewatering pumps operate can significantly impact your project efficiency and outcomes.

By mastering the operation of dewatering pumps, you’ll improve your ability to handle water-related challenges. Investing in the right pump technology can be transformative.

Mastery of these systems ensures sustained performance and optimal results, enhancing your project’s success.

2. Types of Dewatering Pumps

Various dewatering pumps, each designed for specific applications, facilitate efficient water removal.

In general, these pumps can be categorized into centrifugal (self-priming), diaphragm, submersible, and wellpoint systems, which vary in their mechanisms and applications to tackle diverse water-related challenges.

Each type offers unique “fit-for-purpose” benefits, ensuring the ‘right tool for the job.’

2.1. Centrifugal Pumps

Centrifugal pumps are widely used in numerous industrial applications, translating rotational energy into hydrodynamic energy for effective water discharge. Their simplicity and high efficiency make them a popular choice in dewatering operations.

The core mechanism involves a rotating impeller that accelerates the fluid outward, creating a low-pressure area at the pump’s center. This action allows the efficient transfer of liquid from one point to another.

Centrifugal pumps can handle fluids containing large solids up to 3” in diameter.

Key benefits include easy maintenance and a modular design that simplifies part replacement. Engineered for reliability, these pumps minimize downtime and maximize operational efficiency. When integrated with advanced priming systems, they achieve quick start-up times, ensuring effective water removal in challenging environments.

2.2. Submersible Pumps

Submersible pumps are designed to operate while fully submerged in the fluid they are pumping. These pumps are essential for applications requiring high efficiency and low maintenance.

- High Efficiency: Submersible pumps minimize energy loss, making them highly efficient.

- Low Noise: Their submerged operation results in lower noise levels.

- Easy Installation: They are straightforward to install and operate.

- Versatile Applications: Suitable for dewatering, sewage handling, and more.

These pumps have an integrated hermetically sealed motor, protecting it from fluid ingress. This feature ensures long service life and reliability under harsh conditions.

Submersible pumps excel in removing water from basements, wells, and construction sites swiftly and efficiently. Their robust construction and design ensure they perform under demanding circumstances.

2.3. Diaphragm Pumps

Diaphragm pumps are vital in managing challenging fluids, including slurries, viscous materials, and abrasive substances. They function using a flexible diaphragm driven by a mechanical, hydraulic, or pneumatic actuation method.

These pumps excel in applications requiring the safe transfer of hazardous materials.

Notably, diaphragm pumps can handle high solid-content fluids, even in extreme conditions, maintaining high efficiency.

In situations where air or vapor is present, these pumps continue to operate effectively.

They are indispensable for industries such as mining, chemical processing, and wastewater management, ensuring consistent performance without frequent maintenance. Additionally, diaphragm pumps’ self-priming capabilities make them a go-to solution for diverse fluid handling tasks.

Ultimately, the ease of maintenance and robust performance solidify their place in any advanced dewatering strategy, giving you confidence in tackling even the toughest fluid management challenges.

3. Key Features to Consider

When choosing a dewatering pump, a number of indispensable characteristics must be prioritized. Consider modular canopy designs for ease of replacement, environmentally friendly engines, and non-clogging impellers for reliable performance. Also, evaluate the inclusion of advanced priming systems and cooling mechanisms to ensure longevity and minimal maintenance. These features collectively contribute to a robust, efficient dewatering solution capable of handling even the most challenging applications.

3.1. Flow Rate

Understanding the flow rate of your dewatering pump is essential for optimal performance.

- Measure Pump Capacity: Determine the gallons per minute (GPM) or liters per second (L/s) your pump discharges.

- Evaluate Application Requirements: Match the pump’s flow rate to your specific project needs.

- Consider Environmental Factors: Factor in variables such as fluid viscosity and solid content that may affect flow.

- Monitor Performance: Regularly check for variations to maintain consistent and efficient operation.

Properly assessing the flow rate ensures your pump meets job requirements without overexertion.

Accurate flow measurement can significantly impact operational efficiency and project timelines.

3.2. Pump Power

Selecting the appropriate power source for your dewatering pump is crucial for efficiency and performance, ensuring your project runs smoothly.

Power options include diesel engines, electric motors, and hydraulic drives.

Each type of power source offers various advantages depending on project needs and site conditions, such as fuel availability, maintenance, and operational costs.

Diesel engines provide robust and reliable power, ideal for remote locations without access to electricity. Electric motors offer quieter operation and lower emissions, making them suitable for urban environments. Hydraulic drives are highly efficient and allow for precise control, perfect for specialized applications requiring variable speeds. Choose wisely to maximize efficiency and effectiveness.

3.3. Material Construction

Prime-Flow Pumps are designed with durability and longevity in mind, employing high-quality materials for superior performance.

- Hot Galvanized Components: Canopy steel structures, including the base, fuel tank, panels, and roofs.

- Modular Canopy Design: Enables easy replacement of damaged sections.

- Stackable Design: Optimizes storage and space management.

- Forklift Ports: Located on all four sides for flexible loading and unloading.

These materials ensure the pumps withstand harsh environmental conditions while maintaining structural integrity.

Galvanized options for skids and trailers enhance versatility and extend service life.

4. Dewatering Pump Applications

Dewatering pumps are indispensable in a multitude of industries. They are engineered to perform efficiently in demanding environments.

In the construction industry, dewatering pumps are essential for maintaining dry working conditions (e.g., excavations and foundations), reducing the risk of structural damage, and ensuring the safety of your workforce. Additionally, these pumps enable swift water removal from flooded areas, facilitating prompt project advancement.

Terms like “bypass” and “irrigation” further illustrate their versatility across various sectors.

4.1. Construction Sites

Imagine a bustling construction site with excavations underway and an unexpected groundwater issue halting your progress.

Since 2016, Dynapro’s advanced Prime-Flow dewatering pumps have provided crucial support to construction projects. They allow you to maintain dry, stable working conditions by effectively managing water levels.

With the Eco-Friendly Vacuum Priming system, these pumps quickly resolve water issues, ensuring your construction timelines remain on track. The dry-running protection system allows the pumps to operate safely without constant surveillance.

Wide water passage impellers are perfect for handling everything from rainwater to sludge, even in heavy-duty environments. This means you can confidently tackle the most demanding dewatering tasks.

Dynapro’s cutting-edge dewatering pumps are the cornerstone of many successful construction projects.

4.2. Mining Operations

In the mining industry, managing water effectively is critical to your operation’s success.

Dynapro’s Prime-Flow dewatering pumps stand out in mining applications, delivering unparalleled reliability and efficiency. Their robust construction ensures they can handle abrasive solids, high-pressure environments, and variable water conditions, making them indispensable assets in the complex world of mining dewatering.

Our Eco-Friendly Vacuum Priming system primes quickly and efficiently, even under the most challenging conditions. The advanced cooling system ensures low operating temperatures, significantly extending the lifespan of the pumps, crucial for continuous mining operations.

Additionally, the innovative non-clogging impeller and self-cleaning mechanism allow these pumps to handle everything from sludge and wastewater to large solids. This technology minimizes downtime and ensures your mining operation runs smoothly. Dynapro’s dewatering pumps are engineered to support your overarching goal of operational excellence and sustainability in mining.

4.3. Flood Management

Effective flood management requires reliable and efficient dewatering solutions.

- Site Assessment: Evaluate flood-prone areas to determine pump placement.

- Pump Selection: Choose pumps based on water volume and types of solids present.

- Installation: Secure and connect pumps to strategically mapped positions.

- Monitoring: Implement continuous monitoring for optimal performance.

- Maintenance: Regularly inspect and maintain pumps to ensure long-term reliability.

Dewatering pumps effectively manage floodwaters by rapidly removing water from affected areas.

Our technology ensures pumps operate efficiently, even under challenging conditions, thereby mitigating flood damage.

5. Installation and Maintenance Tips

Proper installation of your dewatering pump is essential to maximize efficiency and prolong its lifespan. Ensure that the unit is level, securely anchored, and the inlet and outlet hoses are unobstructed.

Regular maintenance involves inspecting seals, checking oil levels, and verifying the integrity of the impeller. This proactive approach extends the operational life of the pump.

5.1. Proper Setup Guidelines

Proper setup of your dewatering pump ensures optimal performance and effective water discharge for extended longevity.

- Site Assessment: Evaluate the site to determine the best pump placement.

- Pump Selection: Choose pumps based on water volume and types of solids present.

- Installation: Secure and connect pumps to strategically mapped positions.

- Monitoring: Implement continuous monitoring for optimal performance.

- Maintenance: Regularly inspect and maintain pumps to ensure long-term reliability.

Ensuring correct setup mitigates potential operational issues and maximizes efficiency.

Following these steps rigorously guarantees the most effective use of your dewatering pump system.

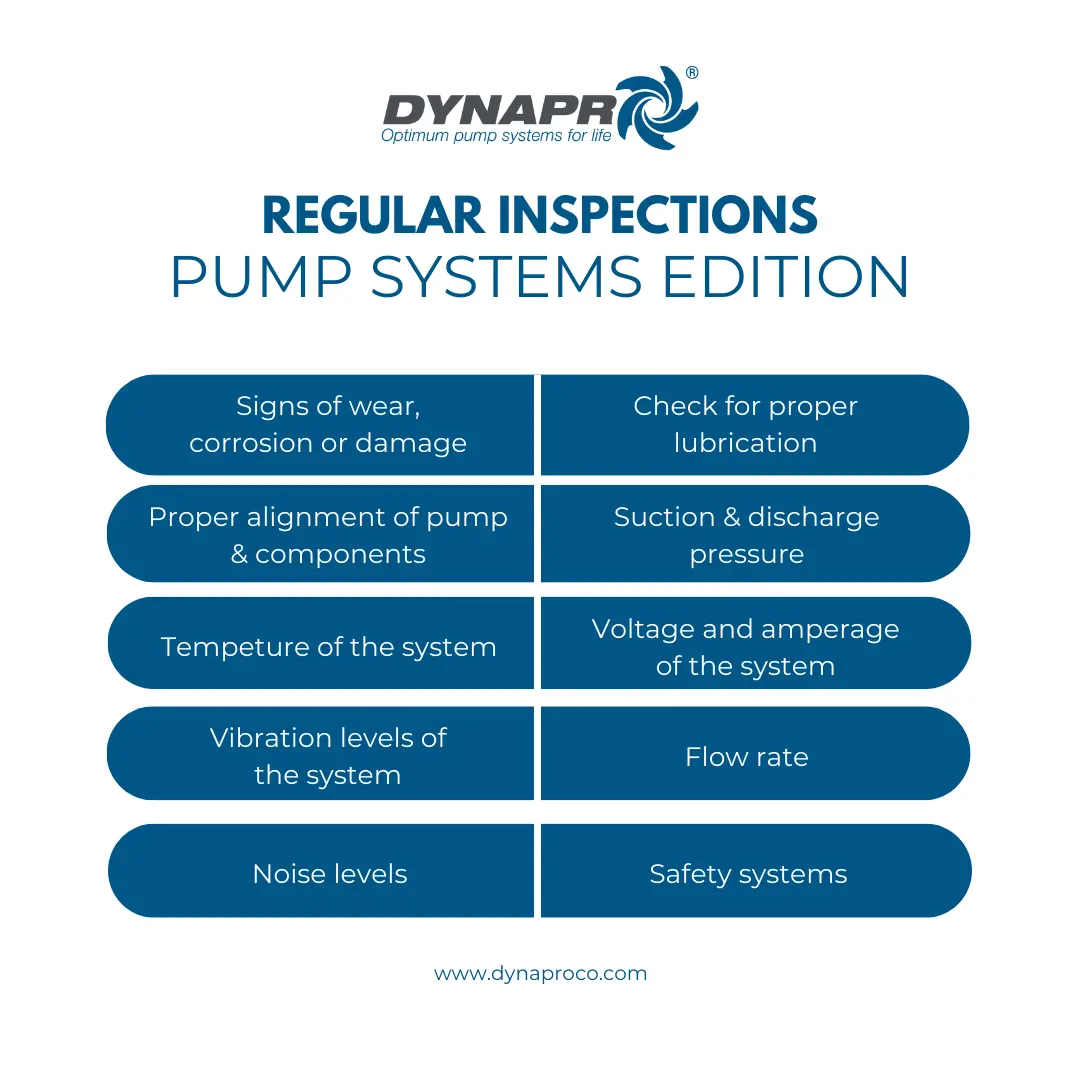

5.2. Regular Maintenance Practices

When it comes to dewatering pump longevity, regular maintenance is paramount to avoiding unexpected downtimes.

Begin by scheduling routine inspections for your pump’s critical components, such as the mechanical seals and impeller. These inspections help identify wear and tear early, preventing major failures.

Check the oil levels in the oil chamber and reservoir frequently. Maintaining proper oil levels ensures the efficient operation of the pump and extends the lifespan of the mechanical seals.

Examine the vacuum pump’s cooling system regularly. Ensure it is free of any blockages and that the water flow is consistent, helping to maintain a low operating temperature for optimal performance.

Implementing these regular maintenance practices guarantees your dewatering pump operates at peak efficiency, safeguarding your investment.

5.3. Troubleshooting Common Issues

Even with rigorous maintenance routines, issues may arise that hinder the efficacy of your dewatering pump. Understanding the root causes can lead to prompt and efficient solutions.

If your pump fails to prime, first check for air leaks or blockage in the suction line.

Additionally, ensure the vacuum pump is operating as expected. High air processing capacity and a strong vacuum should be verified.

Should you observe abnormal noises or vibrations, inspect the impeller and wear rings for possible damage.

Persistent overheating could be a sign of inadequate cooling. Verify that pressurized water flow is maintained and is cooling the vacuum pump effectively.

Low flow rates might indicate a clogged impeller. The innovative non-clogging impeller design should be capable of handling large solids, but occasional checks are necessary.

In summary, recognizing these common issues early is vital for sustaining optimal pump performance. Prompt troubleshooting ensures minimal disruption and maintains functionality.

6. Choosing the Right Dewatering Pump

When selecting a dewatering pump, consider the specific features and applications that match your operational needs, such as site conditions, flow requirements, and fluid characteristics. Evaluating the pump’s self-priming capabilities, dry running protection, and non-clogging impeller functionalities is essential to ensure seamless and reliable performance.

Carefully assessing these factors ensures that your investment in a dewatering pump aligns with your project goals and environmental responsibilities. Your choice significantly impacts efficiency, maintenance, and overall operational success.

advance

6.1. Assessing Your Needs

Begin by analyzing the unique demands of your dewatering project. Identify the specific operational challenges and requirements that must be addressed, and the vital factors, such as flow rates and fluid characteristics.

Evaluate the site conditions to ensure the pump can handle the environmental demands.

Create a comprehensive checklist detailing operational parameters, such as necessary flow rates, potential solids in the fluid stream, and the site’s geographical constraints. This helps narrow down options to those pumps ideally suited to your task.

This meticulous evaluation process not only optimizes the selection but also enhances operational efficiency and longevity. By understanding your project’s unique needs, you can confidently choose a dewatering pump that excels in both performance and reliability, setting a foundation for success.

6.2. Comparing Different Models

When comparing different models of dewatering pumps, you must consider several critical factors, including application suitability, efficiency, and ease of maintenance.

Each model comes with distinct features tailored to specific operational needs.

Opt for models that incorporate advanced technologies like self-priming systems and non-clogging impellers. These attributes can significantly enhance performance, especially in challenging environments that involve handling solids, debris, or sludge.

Finally, analyze each model’s construction and design features, such as modular canopies and advanced cooling systems. By doing so, you ensure that your chosen pump not only meets your operational demands but also offers durability and ease of service. Comparing these critical aspects will guide you in making an informed decision that aligns perfectly with your dewatering needs.

6.3. Cost vs. Performance

When considering a dewatering pump, how important is the balance of cost against performance attributes?

In 2023, Dynapro introduced its Prime-Flow Pumps, setting a new standard by combining cutting-edge technology with cost-effectiveness. The innovative modular design of these pumps minimizes replacement costs by allowing easy disassembly and part replacement.

It’s not just about initial cost savings; Dynapro’s eco-friendly vacuum priming systems eliminate routine maintenance costs. These systems feature a sleep mode, which extends the pump’s lifecycle, requiring fewer part replacements and reducing operational downtime.

Moreover, features such as the advanced cooling system and non-clogging impellers ensure that your pump performs optimally under harsh conditions. High efficiency and low maintenance translate to significant long-term savings and improved ROI for your projects.

In summary, Dynapro’s Prime-Flow Pumps offer a perfect balance between cost and performance, making them an ideal choice for demanding environments.

Which pump is best for dewatering?

When selecting the best pump for dewatering, consider the Dynapro Prime-Flow Pumps. These pumps are engineered with advanced technologies and features that make them ideal for dewatering applications. Here’s why:

- ECO-Friendly Vacuum Priming Innovation: The EVP system utilizes third-generation vacuum pump technology, enabling rapid priming within seconds. This system offers high air processing capacity, strong vacuum, low operating temperature, and maintenance-free operation without oil or mechanical seals.

- Prime-Sleep-Prime (P-S-P) Auto Switch System: The EVP system automatically transitions to sleep mode once priming is complete, minimizing daily maintenance and part replacement throughout its lifecycle.

- Dry Running Protection System: These pumps can operate dry for extended periods without damaging their mechanical seals, thanks to a protection system comprising a standard mechanical seal, oil chamber, and oil reservoir connected by hoses to form an oil circulation loop.

- Advanced Cooling System: A pressurized cooling flush water is introduced from the centrifugal pump’s water passage into the vacuum pump’s water jacket, maintaining a low operating temperature and significantly extending the EVP system’s lifespan.

- User-Friendly Disassembly Design: The vacuum pump’s cover can be easily removed for inspection or replacement. The centrifugal pump’s impeller, wear ring, and mechanical seal are also accessible without removing the diesel engine or pump frame, facilitating straightforward maintenance.

- Innovative Non-Clogging Impeller: Equipped with wide water passage impellers that can handle solids with a diameter of 3” or larger, making these pumps ideal for critical applications like sewage, sludge, and fluids containing large stones.

- Self-Cleaning Mechanism: The stuffing box features a unique structure that mixes and discharges solids, preventing clogging of the mechanical seal spring and avoiding seal failures.

- Versatile Technology: The powerful EVP Priming System is suitable for various fluid industry applications, including dewatering, bypass, firefighting, lift station backup, mining, irrigation, water transfer, and well point systems.

With these advanced features, Dynapro Prime-Flow Pumps set the gold standard for dewatering operations, ensuring efficiency, reliability, and minimal maintenance.

What is the Difference Between Submersible and Dewatering Pumps?

When choosing the right pump for your application, it’s essential to understand the differences between submersible pumps and dewatering pumps. Both types serve distinct purposes and offer unique advantages.

Submersible Pumps

Design and Operation:

- Submersible pumps are designed to operate while fully submerged in the fluid they are pumping.

- They are typically used for applications where the pump needs to be placed inside a well, tank, or other fluid-filled environments.

- The motor is sealed to prevent water ingress, ensuring reliable operation underwater.

Applications:

- Ideal for deep well pumping, sewage pumping, and underwater applications.

- Commonly used in residential, commercial, and industrial settings for tasks like draining flooded basements, wells, and sumps.

Advantages:

- Efficient Operation: Being submerged, these pumps are highly efficient as they do not require priming.

- Quiet Performance: Operating underwater reduces noise levels.

- Space-Saving: Installed within the fluid, they save surface space.

Dewatering Pumps

Design and Operation:

- Dewatering pumps are designed to remove water from surfaces or shallow areas.

- They are typically used in construction sites, mines, and other areas where water needs to be removed quickly and efficiently.

- These pumps can be either submersible or non-submersible, depending on the specific application.

Applications:

- Ideal for construction dewatering, mining operations, and emergency flood response.

- Used for removing water from trenches, pits, and other surface-level areas.

Advantages:

- Versatility: Can handle a variety of water removal tasks, including those involving solids and debris.

- Portability: Often designed for easy transport and quick setup.

- High Capacity: Capable of moving large volumes of water quickly.

Key Differences

- Installation: Submersible pumps are installed underwater, while dewatering pumps can be used both underwater and on the surface.

- Applications: Submersible pumps are best for deep well and underwater applications, whereas dewatering pumps are suited for surface water removal and shallow areas.

- Design: Submersible pumps have sealed motors to prevent water ingress, while dewatering pumps may have different designs based on their specific use cases.

Understanding these differences will help you choose the right pump for your needs, ensuring efficient and effective water management.