Without proper dewatering, operations risk severe disruptions.

Just as a ship can’t sail without navigation, functionality relies on precision removal of water.

Reliable dewatering pumps, including wellpoints and deepwells, are essential in mining, industrial, and construction operations. Flooded sites can halt progress and cause significant financial losses.

Dynapro Pumps delivers solutions.

1. Introduction to Dewatering Pumps

When it comes to mining, industrial, and construction operations, efficient water management, such as the use of wellpoints, is critical. These industries consistently face challenges related to water infiltration and accumulation. Such challenges can drastically hinder productivity, safety, and financial outcomes.

Dewatering pumps are essential tools.

Their role extends beyond simple water removal; they ensure the seamless continuation of operations. By effectively managing water levels, projects stay on schedule and operations remain smooth.

Understanding dewatering pumps and their application, including the use of deepwells, helps ensure optimal performance in these vital industries. Every operation can benefit significantly from this knowledge.

Dynapro Pumps stands at the forefront of providing high-quality dewatering solutions without the exorbitant costs associated with other brands. Our pumps are designed for those who demand reliability and performance.

With Dynapro Pumps, you’re not just getting a tool; you’re investing in a trusted partner that will help you achieve operational excellence.

2. Importance of Dewatering in Various Industries

In industries like mining, construction, and industrial operations, effective dewatering is essential to maintain productivity and safety. Water accumulation can lead to dangerous conditions, equipment damage, and costly delays.

Reliable dewatering pumps keep operations running smoothly and on schedule. By choosing Dynapro Pumps, you invest in dependable, cost-effective solutions.

2.1 Dewatering in Mining

Efficient dewatering in mining operations is indispensable—it minimizes environmental impacts and enhances operational efficiency.

Dynapro Pumps significantly reduce downtime by providing unparalleled reliability, helping you maintain peak productivity and environmental compliance.

Our pumps are engineered to handle the demanding conditions of mining sites, ensuring longevity and consistent performance. Without effective dewatering solutions, water intrusion can cause catastrophic damage and endanger workers’ safety.

By opting for Dynapro Pumps, you are not only investing in the highest quality equipment but also ensuring robust operational capability and long-term success in your mining ventures.

2.2 Dewatering in Construction

Effective dewatering in construction is essential to maintain safe and stable work environments.

- Foundation stability: Prevents groundwater from weakening foundation soils.

- Excavation safety: Ensures dry conditions for safe excavation.

- Material protection: Keeps construction materials dry and in optimal condition.

- Schedule adherence: Minimizes delays caused by water accumulation.

- Cost efficiency: Reduces potential damage costs and project delays.

Dynapro Pumps deliver unmatched performance in construction dewatering applications. They stand out for their durability and efficiency.

Investing in Dynapro means choosing reliability that keeps your construction projects on track and within budget.

2.3 Dewatering in Industrial Operations

Effective dewatering is vital in industrial settings due to its role in maintaining operational efficiency and safety.

In 2016, a prominent engineering firm experienced significant productivity gains through the strategic use of dewatering pumps. By effectively managing unwanted water, they avoided costly downtime and equipment damages, showcasing the importance of reliable dewatering systems.

We understand how critical it is to ensure a dewatering system’s performance and reliability in heavy industrial environments. Our Dynapro Pumps are specifically designed to withstand rigorous demands and deliver consistent, high-performance water removal.

When reviewing the landscape of industrial operations, choosing a pump that provides not only capacity but also durability is key. At Dynapro, our pumps are built to excel in even the harshest conditions, offering the highest quality without the premium price tag.

Partner with Dynapro and experience the benchmark of excellence in industrial dewatering solutions.

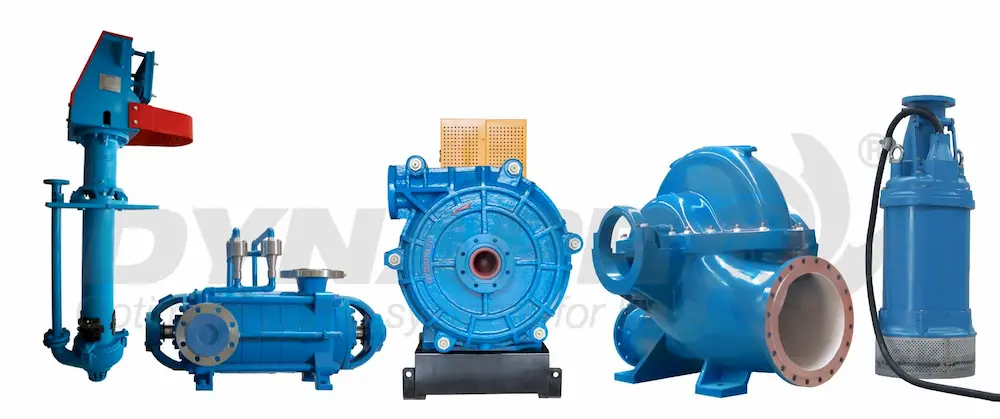

3. Types of Dewatering Pumps

Understanding the different types of dewatering pumps is essential for selecting the best equipment for your needs. Generally, these pumps can be categorized into centrifugal pumps, submersible pumps, and diaphragm pumps, each with its unique advantages and applications.

Centrifugal pumps are ideal for larger volumes and have high flow rates, making them suitable for significant dewatering projects. Submersible pumps, on the other hand, are versatile and excellent for underwater operations, effectively handling submerged conditions. Diaphragm pumps are invaluable in situations where dealing with muddy or slurry-filled areas, providing reliable performance.

These various “types of dewatering pumps” ensure that regardless of your specific requirements, there is a suitable solution available.

3.1 Centrifugal Pumps

Centrifugal pumps transform rotational energy into fluid movement.

These pumps operate using a rotating impeller to create a low-pressure zone that draws water in. The liquid is then flung outwards by centrifugal force, allowing it to gain velocity and flow out under higher pressure. This makes centrifugal pumps the ideal choice for high-volume dewatering applications, particularly in mining, industrial, and construction settings where rapid and efficient water removal is critical.

Their design is simple yet robust.

Operational efficiency of centrifugal pumps depends on – and is evidenced by – their ability to move large volumes at quick rates without excessive energy consumption or maintenance.

With Dynapro Pumps, you’re leveraging decades of design innovation and rigorous field testing. Our centrifugal pumps ensure maximum uptime and minimal maintenance, positioning you ahead of the curve in 2023 and beyond. We prioritize quality and performance, offering the best without the unwarranted premium prices of other brands. Trust Dynapro to deliver reliability and excellence in all your dewatering projects.

3.2 Submersible Pumps

Submersible pumps are a game-changer in dewatering efforts, designed to function completely underwater.

- High Versatility: Ideal for a variety of applications including mining, industrial, and construction.

- Enhanced Efficiency: Operates directly in the fluid, eliminating the need for priming.

- Compact Design: Requires minimal space and can be transported with ease.

- Robust Construction: Built to withstand harsh environments and continuous operation.

These pumps stand out due to their ease of installation and minimal maintenance requirements.

Using Dynapro Pumps, you’ll benefit from advanced engineering at a competitive price.

Choose Dynapro for durable, efficient submersible pumps that excel in the toughest conditions.

4. Choosing the Right Dewatering Pump

Choosing the right dewatering pump is crucial for efficient and uninterrupted operations, whether in mining, industrial, or construction sectors. Identifying the correct pump type involves evaluating factors such as fluid type, head requirements, flow rate, and pump material, ensuring a bespoke solution tailored to your project’s specific needs. Dynapro Pumps offers an array of high-quality options that balance performance and cost-effectiveness, ensuring you don’t compromise on excellence. Visit Dynapro Pumps and Dewatering Pumps to explore our solutions.

4.1 Assessing Your Project Needs

Before diving into pump selection, we must first understand the unique requirements of your project. Defining your project’s needs involves evaluating several critical factors, aligning them with an appropriate dewatering solution.

Our primary aim is to ensure you make a well-informed decision that yields optimal results.

Start by considering the nature of the fluid to be handled, including its viscosity and potential contaminants. These characteristics will greatly influence the type of pump you need.

Next, evaluate the site conditions to determine the head requirements and flow rate necessary for effective operation. This assessment ensures that the dewatering system will perform efficiently under your specific circumstances.

Taking stock of these variables enables us to recommend tailored solutions that fit your exact specifications, eliminating the guesswork and ensuring seamless operation from the outset.

Remember, when it comes to dewatering, there’s no one-size-fits-all approach. Careful preparation and precise planning pave the way for success. Explore our range at Dynapro Pumps to find the ideal match for your project.

4.2 Evaluating Pump Performance

Accurately assessing pump performance starts with understanding key metrics that define efficiency and reliability.

First and foremost, it’s essential to look at a pump’s head capacity and flow rate, ensuring these align perfectly with your project’s needs. You need pumps that can handle the site-specific demands, taking into consideration aspects like distance, elevation, and fluid type.

The power efficiency and fuel consumption of your dewatering pump also play a critical role. An efficient pump minimizes operating costs and maximizes uptime, both of which are crucial for maintaining productivity and profitability in mining and industrial applications.

Finally, consider the durability and maintenance requirements of the pump. High-quality builds like those from Dynapro Pumps offer robust construction designed for longevity, reducing downtime and maintenance costs. With our expertise, you can trust that your dewatering pump will stand up to the demanding conditions of your project, ensuring continuous, trouble-free operation.

4.3 Budget Considerations

Investing in a dewatering pump is a significant decision, requiring thoughtful budget planning.

When considering your budget, it’s critical to balance upfront costs with long-term savings. Dynapro Pumps provides an excellent cost-to-value ratio, ensuring you get premium performance without the premium price tag. Remember, the efficiency and reliability of the pump can drastically impact your overall project costs, from reducing downtime to minimizing maintenance expenses.

Additionally, factor in the scalability of the dewatering pump to meet future needs. By selecting versatile and durable equipment, like those from Dynapro, you ensure your investment remains valuable over time. A slightly higher initial investment can prevent costly replacements and repairs down the line, enhancing your project’s financial health.

In conclusion, prioritize comprehensive assessments when making budget decisions for dewatering pumps. Our offerings at Dynapro Pumps are designed to deliver maximum value, ensuring your operations run smoothly, cost-effectively, and sustainably. By investing wisely, you’re not only safeguarding your project’s current needs but also securing its long-term success and profitability.

5. Maintaining Dewatering Pumps

Routine maintenance is essential to maximize the lifespan and performance of your dewatering pumps. Regular inspections and timely servicing prevent costly breakdowns, ensuring continuous and efficient operations. Our Dynapro pumps are designed with ease of maintenance in mind, offering straightforward access to critical components, making upkeep less cumbersome and more effective. Remember, proactive care today translates to long-term savings and operational reliability, which are crucial in the demanding environments of mining, industrial, and construction sectors.

5.1 Regular Maintenance Tips

For optimal performance and longevity of your dewatering pump, adhering to a regular maintenance schedule is critical.

- Inspect seals and gaskets: Regularly check for wear and tear to avoid leaks or system failures.

- Monitor fluid levels: Ensure the pump’s lubrication and cooling fluids are at appropriate levels.

- Check electrical connections: Tighten any loose wires and inspect for corrosion or damage.

- Clean filters and screens: Prevent clogging and ensure a consistent flow rate by clearing debris.

- Test the pump operation: Periodically run the pump to detect any irregular sounds or vibrations.

Timely attention to these maintenance tips can prevent unexpected downtimes and costly repairs.

Remember, proactive maintenance promotes efficiency and helps in identifying minor issues before they escalate.

5.2 Troubleshooting Common Issues

Even with regular maintenance, dewatering pumps can encounter issues that need prompt attention.

- Pump not starting: Check for power supply issues or a tripped circuit breaker.

- Reduced flow rate: Inspect for clogged filters or a blockage in the hose or pipe.

- Overheating: Ensure proper ventilation and check for obstructions in the cooling system.

- Strange noises: Listen for cavitation or check for foreign objects within the pump.

- Leakage: Examine seals and gaskets for wear or improper installation.

Proactively addressing these common problems can minimize operational downtime.

Remember, timely troubleshooting ensures pump longevity and consistent performance.

5.3 Extending Pump Lifespan

Regular maintenance extends the life of dewatering pumps.

Scheduled inspections should not only focus on worn parts but also on the pump’s overall performance. This approach ensures that even minor irregularities are promptly corrected, contributing to prolonged operational efficiency and reduced downtime. Additionally, paying attention to the environmental conditions in which the pump operates can prevent premature wear.

Using high-quality parts ensures reliability.

Regular oil changes and lubrication are – at the very least – as crucial as timely part replacements for any moving machinery. We must emphasize the importance of using manufacturer-recommended products to prevent avoidable wear-and-tear.

Implementing a comprehensive predictive maintenance plan guarantees the continuous optimal performance of your equipment, aligning with the best industry practices of 2023 and reflecting the next level of maintenance excellence. By diligently following these steps, we not only safeguard our investment but also maximize operational efficiency and longevity.

6. Advantages of Using Dynapro Dewatering Pumps

Our Dynapro Dewatering Pumps are engineered to deliver unmatched reliability in demanding environments. Each pump is subjected to rigorous testing to withstand the harshest conditions.

With Dynapro, you receive superior performance without the premium price tag. Our pumps are cost-effective and come with unparalleled durability.

Built with advanced technology, these pumps offer exceptional efficiency and minimal maintenance, translating into significant cost savings for mining, industrial, and construction operations.

The robust construction of Dynapro Dewatering Pumps ensures they can handle high volumes of water quickly and efficiently, making them indispensable for job sites that can’t afford downtime. From rigorous quality control to innovative design features, Dynapro remains committed to providing the best solutions for all dewatering needs. For additional information and to explore our product line, please visit www.dynaproco.com and www.dewateringpumps.com.

7. How to Purchase Dynapro Dewatering Pumps

Purchasing Dynapro Dewatering Pumps is a streamlined process designed to accommodate your specific needs, ensuring a hassle-free experience from start to finish. Leveraging our comprehensive online resources, procuring the ideal pump has never been more straightforward.

Begin your journey by visiting our official websites, www.dynaproco.com and www.dewateringpumps.com.

Explore our extensive product catalog to identify the best dewatering pump for your application. Pay close attention to specifications and performance metrics.

Should you require additional guidance, our team of experts is readily available to offer personalized recommendations and in-depth insights. Connecting with us is simple, and we’re committed to assisting you.

Before finalizing your purchase, compare features and reviews to corroborate your selection. Our user-friendly interface ensures a seamless transaction process.

Ultimately, you will find that Dynapro’s excellence in engineering and customer service elevates your purchasing experience. Trust in our expertise to provide industry-leading dewatering solutions tailored to your requirements.

What is the dewatering process?

Dewatering is the process of removing water from a site, typically to make it safe for further operations. Whether it’s standing water on a construction site, groundwater in a mining pit, or industrial wastewater, effective dewatering is essential.

In mining, dewatering ensures that pits remain dry, protecting workers and machinery from hazards associated with water accumulation. This keeps operations running smoothly and safely, preserving productivity. Comprehensive dewatering strategies are a critical part of planning and executing any successful mining project.

For construction, dewatering helps to create stable soil conditions, preventing delays and structural issues. It allows work to continue uninterrupted by adverse water conditions, ensuring projects stay on schedule. The efficiency of the dewatering process can significantly impact the overall timeline and success of the project.

Industrial operations rely on dewatering to manage waste and water byproducts, maintaining environmental compliance and operational efficiency. Proper dewatering practices can lead to significant cost savings and enhance operational effectiveness. This is particularly vital in industries where water management is a part of everyday operations.

Reliable dewatering pumps are the backbone of efficient water removal. Choosing the right equipment can minimize downtime, maintain safety, and ensure the success of your project.

What are the three types of dewatering?

In the realm of dewatering, three primary methods stand out: wellpoint systems, sump pumping, and deep well systems. Each method holds a defining place in managing groundwater and surface water in excavation sites, ensuring minimal downtime and efficient operations.

Wellpoint systems involve installing a series of small-diameter wells equipped with pumps to lower the groundwater table before excavation begins. By doing so, we can ensure a dry and stable work site, which is particularly crucial in construction projects with shallow excavation depths. These systems are versatile and can be adapted to various soil conditions.

Sump pumping is another widely used method where water is collected in sumps strategically placed around the excavation site. Submersible pumps then efficiently remove the accumulated water, maintaining a dry environment. This method is prominent in both mining and construction due to its simplicity and effectiveness in handling large volumes of water.

With deep well systems, a series of deep wells equipped with submersible pumps are used to extract groundwater from significant depths. This method is ideal when dealing with high groundwater levels and large-scale excavation projects. By lowering the water table around excavation sites, deep well systems enhance stability and safety, facilitating uninterrupted progress. These dewatering techniques play a pivotal role in ensuring seamless operation within mining, industrial, and construction spheres.

What is the common method of dewatering?

Pump and sump systems are widespread.

In these setups, pumps draw water from sumps or collection pits. This method efficiently prevents water accumulation at construction sites or mines, ensuring operations continue smoothly. The process involves strategically placing pumps to remove water as it enters, maintaining a dry and safe site.

Ensuring optimal dewatering is crucial.

Using high-quality dewatering pumps is essential, as it impacts downtime. Investing in reliable equipment keeps operations running efficiently. Choose a trusted brand like Dynapro Pumps. Our pumps provide top-tier performance without the prohibitive costs of other brands, making us the optimal choice for your needs.

What is dewatering also known as?

Dewatering is an essential process employed to remove accumulated water from work sites, particularly in mining, industrial, and construction operations.

This vital function ensures a safe and stable working environment by mitigating the risks associated with waterlogged areas. Effective water management allows operations to proceed without unnecessary delays.

The process also goes by other terms, including “water pumping” and “water extraction.” These synonymous terms all refer to the act of efficiently relocating water from one location to another.

Among the reliable equipment required for dewatering, pumps play a pivotal role. Choosing the right pump can significantly enhance operational efficiency and resilience.

At Dynapro Pumps, we excel in providing high-quality dewatering solutions. Our products offer exceptional performance and durability at a competitive price, making them an ideal choice for demanding environments.