If you dewater deep excavations for basements, shafts, or tunnels, you already know that efficiency, reliability, and control matter more than anything. Deep well dewatering gives you that control by creating drawdown at depth rather than fighting suction limits at the surface. When designed correctly, it provides uniform groundwater lowering, stable excavation faces, and fewer surprises. In this guide you get a practical, calculation-first view of design inputs, installation, pump sizing, operation, and monitoring that keeps your site dry and compliant. The intent is to help you tune your next system from the first borehole to the last piezometer reading.

What Is Deep Well Dewatering (When to Use It)

You install a ring or array of bored wells fitted with screens and pumps around the excavation. Submersible or lineshaft vertical turbine pumps lower the water level to a controlled pumping level, creating a cone of depression that overlaps across the site. This method is effective where you need significant drawdown, where aquifers are moderately to highly permeable, or where point-suction systems would stall at 6 to 7 meters of lift.

Use it when:

- Excavations go deeper than about 5 to 6 meters below groundwater.

- Inflows are high and continuous, and wellpoints would require multiple stages.

- Confined or semi-confined units impose artesian heads that must be relieved at depth.

- You want a clear excavation floor and minimal interference with heavy equipment.

Avoid it as a primary method if the aquifer has very low permeability and only drains via consolidation. In those cases, cutoff walls or staged predrainage with supplemental vacuum systems can outperform a pure pumping approach.

Design Inputs & Calculations

Good layouts start with disciplined inputs and a modeling strategy that suits your site.

Key inputs you should pin down:

- Drawdown target at the excavation and at control points outside the site.

- Aquifer type, thickness, layering, anisotropy, and storage (unconfined specific yield or confined storativity).

- Hydraulic conductivity K and transmissivity T = K × saturated thickness.

- Static water level, dynamic water level at target pumping rates, and the expected pumping level in each well.

- Confined heads and relief requirements if pressures are artesian.

- Radius of influence near boundaries, rivers, utilities, or neighboring basements.

- Discharge route, permit conditions, and turbidity limits.

Testing and derived performance indicators:

- Slug and constant-rate pumping tests to estimate K, T, and storage.

- Step-drawdown test to obtain specific capacity (flow per unit drawdown) and to partition well losses.

- Observation wells or piezometers to track static, dynamic, and recovery levels.

- Grain size curves to design screen slot size and gravel pack gradation.

- Sand content measurements during trial pumping to validate screen design and development effort.

Calculations that matter on every project:

- Drawdown and radius of influence. Analytical solutions like Thiem for steady behavior and Cooper Jacob for late-time drawdown give reliable first sizing when geometry is simple. For heterogeneity and nearby boundaries, use numerical models.

- Well spacing. Space wells so cones of depression overlap and yield the target pumping level. In medium sands, spacings of 10 to 30 meters are common; in gravels or fractured rock, you can often open spacing; in layered silts, you may tighten spacing or add intermediate wells.

- Specific capacity checks. Use step tests to confirm that each well can deliver the modeled flow without excessive drawdown or high well losses.

- Head losses. Account for entrance losses at the screen, friction in risers and headers, and minor losses at bends and valves. These add to the pump’s total dynamic head.

- Screen entrance velocity. Keep it low to reduce head losses and sand pumping. Many designers target less than 0.03 m/s at the screen face.

Rules of thumb to use carefully:

- Screen length covering the most transmissive third to half of the aquifer improves yield while controlling entrance velocity.

- Initial flow capacity should cover peak inflows during early drawdown and wet seasons; 1.2 to 1.5 safety factors on calculated flow are common.

Document environmental and structural limits early. Set allowable drawdown at property lines and specify monitoring points to prove compliance.

Deep Well Dewatering: Installation & Header Layout

Design details you lock in before drilling drive performance for the rest of the project.

Well construction basics:

- Well depth. Set the pump intake below the deepest planned pumping level with adequate submergence margin. For submersibles, maintain at least 0.6 to 1.5 meters submergence under all conditions.

- Screen length and slot size. Size slots using native formation grain-size curves. A common criterion is to select a slot that retains roughly 90 percent of the gravel pack while enabling low entrance velocity. Place the screen across the main transmissive zone, usually one third to one half the aquifer thickness.

- Gravel pack. Use a clean, well-graded gravel pack with D50 about 4 to 6 times the D50 of the formation sand. Thickness frequently ranges from 50 to 100 mm around the screen. Seal above with a bentonite or grout plug as required to prevent vertical leakage.

- Well development. Surge, airlift, and pump until fines clear and sand content stabilizes at very low levels in discharge samples. Development increases specific capacity and reduces long-term clogging.

Riser and header design:

- Riser or column pipe. Choose materials compatible with water chemistry and head. PVC and stainless steel are common for risers; HDPE or steel for headers. Include check valves to prevent backflow and water hammer.

- Headers. Use adequately sized headers to keep velocities under 1.5 to 2.0 m/s, limiting friction losses and noise. Place isolation valves and flow meters at each well takeoff for balancing and maintenance.

- Layout. A perimeter loop is typical. Keep runs short and avoid sharp bends to reduce head losses. For large sites, split into zones with separate headers to localize maintenance and reduce pressure drop.

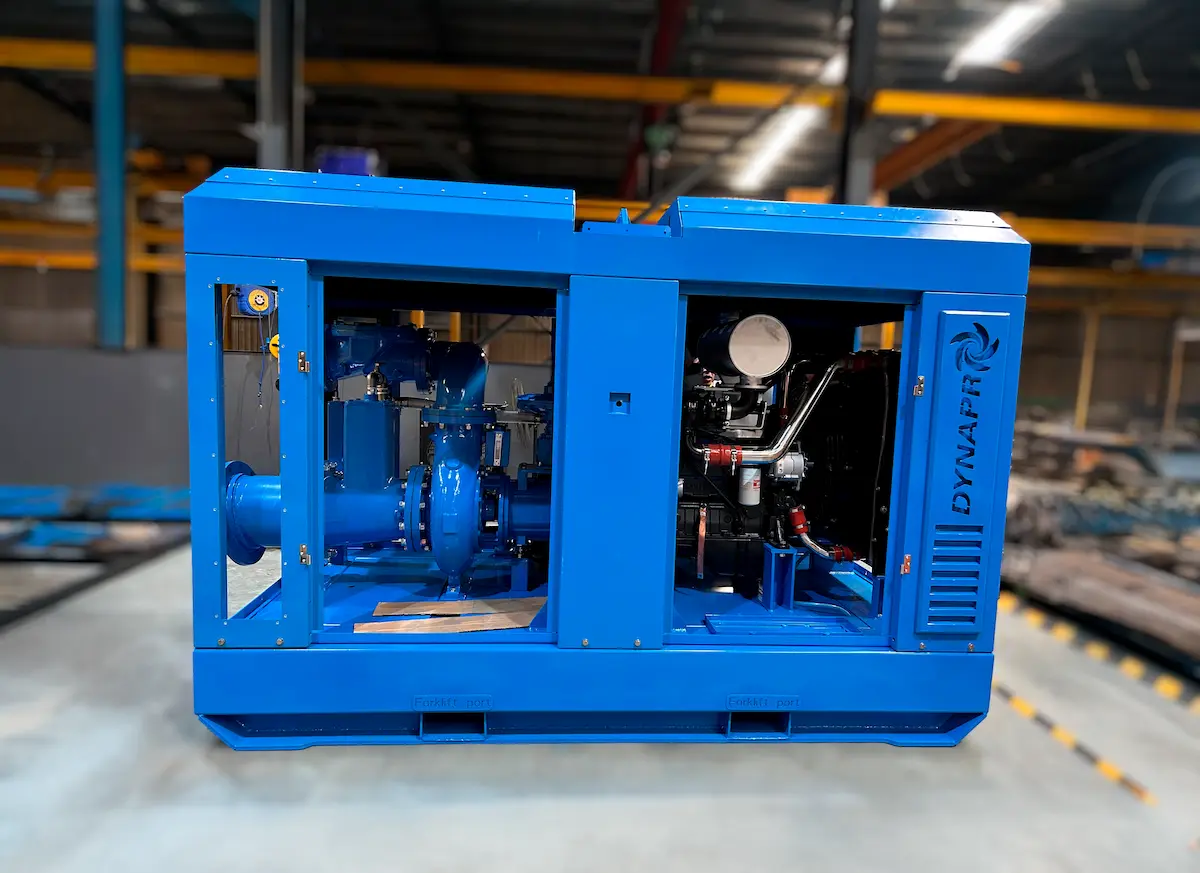

- Power and controls. Provide reliable power with VFDs for speed control, soft starts, and energy savings. For temporary power, specify generator capacity for start-up surges and continuous duty, with attention to noise and fuel efficiency near sensitive receptors.

- Discharge. Route flows to treatment as required by your discharge permit. Provide sampling taps for turbidity checks and ports for water-level transducers. Include sedimentation and filtration units if sand content or fines are observed in early pumping.

A few practical checks before handover:

- Confirm screen entrance velocity at design flow meets your limit.

- Verify meter calibration and pressure transducer placement.

- Test standby power and alarms.

- Record as-built well depths, screens, gravel pack intervals, and pump settings.

Pump Selection & Sizing

Start with the duty point, then pick the machine that hits it with margin.

Define the duty:

- Flow per well and total flow for the array.

- TDH: elevation lift from pumping level to discharge, plus friction and minor losses, plus entrance losses. Reassess TDH at early-time High head high heads and at steady-state.

- Water temperature, expected sand content, and presence of dissolved gases.

- Required turndown range from peak inflow to late-time steady rates.

NPSHa and cavitation:

- Submersible pumps sit beneath water, so NPSHa is generally adequate, which improves reliability at high head.

- Lineshaft vertical turbines place the motor at surface. Ensure NPSHa exceeds NPSHr by comfortable margin at the bowl. Keep suction submergence adequate to avoid air vortices and gas breakout.

Submersible vs lineshaft selection:

- Submersibles. High head, compact, simple installation, no priming, quiet at grade. Ideal for deep pumping levels and narrow casings. Harder to service in place.

- Lineshaft vertical turbines. Surface motor access, flexible motor options, suitable where bowls can remain flooded and access is critical. Sensitive to suction conditions and air leaks in long columns for deeper intakes.

Comparison at a glance:

| Attribute | Submersible multistage | Vertical turbine with lineshaft |

|---|---|---|

| Depth capability | Excellent for deep drawdowns | Good if bowls remain flooded; less suitable at very deep pumping levels |

| NPSHa sensitivity | Low, intake submerged | Higher, suction conditions must be verified |

| Maintenance | Pull to surface for service | Motor at surface; bowls still require pull |

| Noise at surface | Low | Moderate; depends on motor and drive |

| Typical casing sizes | 6 to 16 inches | Larger casings preferred |

Materials and solids:

- Specify abrasion-resistant impellers and bushings if sand content is expected, and install sand separators or shrouds where appropriate.

- Target very low sand content after development. If samples show persistent sand, revisit well development, screen slot selection, and entrance velocity.

Controls and energy:

- Use a variable frequency drive to match flow to aquifer yield and drawdown targets, cut power at partial load, and avoid pressure spikes at startup.

- For generator sets, select units with good fuel efficiency at the expected load range, and consider synchronized smaller sets that stage on and off to match actual load.

- Capture motor current, power, and flow trends to spot efficiency drift.

Power sizing:

- Motor kW = (ρ g Q × TDH) ÷ (pump efficiency × motor efficiency), sized with margin for fouling and seasonal peaks.

- Validate the selected pump against the full envelope of pumping levels from start-up to steady-state, not just the midpoint.

Operation, Monitoring & Troubleshooting

Start-up sequence that avoids surprises:

- Confirm well development is complete and sand content is low.

- Fill headers and expel air.

- Ramp each pump via VFD to initial setpoints; avoid sudden changes.

- Run a step-drawdown test on a few representative wells to verify specific capacity, well losses, and to tune setpoints.

- Set groundwater targets at key piezometers and program alarms.

Monitoring that pays for itself:

- Water levels. Track static and dynamic water levels at observation points inside and outside the excavation. Maintain a dashboard of pumping level in each well.

- Flows and pressures. Meter each well. Compare daily totals to model predictions. Watch for head-loss increases that indicate fouling.

- Power draw. Normalize kW per m³ to identify declining efficiency.

- Water quality. Sample turbidity to stay within discharge permit limits. Use inline turbidity meters where required.

Avoiding common issues:

- Air or gas in pump intakes. Maintain submergence, check seals, and purge lines. Dissolved gas can break out under rapid drawdown; slow the ramp where needed.

- Clogging and sand carryover. If sand content rises, redevelop the affected wells and inspect screen condition. Keep entrance velocity low.

- Pump overheating. Ensure minimum flow limits are honored at low speed and maintain adequate cooling flow around submersible motors. For shrouded units, verify shroud integrity.

- Noise and fuel costs. Keep header velocities modest, isolate vibrating equipment, and optimize generator loading with staged sets and automated load sharing.

When performance drifts, apply structured diagnostics:

- Compare current step-drawdown behavior to commissioning curves. Increased well losses suggest screen encrustation or biofouling.

- If a zone underperforms, check for header restrictions, closed valves, or a failed check valve causing backflow.

- If piezometers outside the site drop more than allowed, throttle flows in the closest wells and review the radius of influence assumptions.

FAQs:

Q1: How do you decide between deep wells and wellpoints?

A: Depth and flow. If drawdown exceeds 5 to 6 meters or inflows are high, deep wells are usually more reliable. Wellpoints fit shallow, very permeable sands with modest flows.

Q2: What is specific capacity and how do you use it?

A: It is discharge per unit drawdown, often in L/s per meter or gpm per foot. Measure it during a step-drawdown test to validate design flows and to spot excessive well losses.

Q3: How do you set well spacing?

A: From transmissivity, storage, and drawdown targets. Use analytical or numerical models to overlap cones of depression. Field test early; 10 to 30 meters is common in medium sands.

Q4: What screen entrance velocity should you target?

A: Keep it low to reduce head losses and sand pumping, commonly under 0.03 m/s. Adjust screen length and diameter to hit that target at design flow.

Q5: How do you choose screen slot size and gravel pack?

A: Base it on formation grain-size curves. Select a slot to retain the gravel pack, and a pack gradation that stabilizes the formation while permitting flow.

Q6: Where does NPSHa matter most?

A: It is critical for lineshaft vertical turbines that rely on suction conditions at the bowl. Submersibles have high available NPSH by design since the pump is submerged.

Q7: Do you need VFDs on every well?

A: Not always, but VFDs on at least the lead pumps in each zone help match inflow, cut energy use, improve noise control, and smooth drawdown.

Q8: What sand content is acceptable?

A: After development, aim for very low sand carryover, often measured in a few parts per million. Sustained sand indicates development or screen issues.

Q9: How do discharge permits affect design?

A: Permits can set turbidity limits, sampling frequency, and allowable volumes. Plan for treatment capacity, sampling taps, and space for settling and filtration.

Q10: What triggers well redevelopment?

A: Declining specific capacity, rising head losses, or increased turbidity. Redevelop with surging or airlifting, and reassess performance with a step test.