Remember the first time you encountered a pump that wouldn’t start?

Self-priming pumps solve this exact issue, offering seamless operation in various applications.

They work efficiently by maintaining a reservoir of liquid, allowing immediate pumping without manual intervention. This design eliminates air pockets that plague standard pumps, ensuring continuous operation.

Self-priming pumps simplify your work.

1. What is a Self-Priming Pump?

Self-priming pumps maintain a reservoir of liquid.

This unique feature enables them to automatically prime themselves, eliminating the need for external priming. The liquid reservoir allows the pump to displace air pockets effectively, ensuring seamless operation and reducing downtime. It’s a distinct advantage, particularly in settings where manual intervention can be labor-intensive or impractical.

They are reliable by design.

Additionally, self-priming pumps can handle a variety of fluids, including slurries and corrosive liquids. This versatility makes them suitable for numerous industrial applications that require regular and intermittent pumping.

In essence, a self-priming pump is engineered to keep your operations running smoothly and efficiently. By integrating intelligent features that mitigate common pumping issues, these pumps offer enhanced reliability and reduced maintenance needs, saving you time and resources.

2. How Does a Self-Priming Pump Work?

Self-priming pumps perform their unique function by creating a vacuum within the pump chamber. This vacuum facilitates the removal of air from the suction line, which is essential for initiating proper fluid flow.

Initially, the pump’s casing must be filled with a sufficient amount of liquid, just enough to cover the impeller. As the pump begins to operate, this liquid is recirculated within the pump, creating a vacuum that draws both fluid and air from the suction line.

The mixed air and fluid are then separated within the pump casing. The air is expelled through the discharge port, while the fluid is retained in the pump chamber, ensuring continuous priming and operation. This cycle repeats itself until the pump is fully primed and operational.

This engineered process ensures that air pockets, commonly known as air binding, are eliminated, allowing for uninterrupted fluid flow. The ability to manage air pockets significantly enhances the efficiency and reliability of self-priming pumps.

In sum, the self-priming pump excels in operations by ensuring a continuous priming capability, even under challenging conditions.

3. Types of Self-Priming Pumps

Self-priming pumps come in various designs.

The most commonly used types include self-priming centrifugal pumps. A centrifugal pump works by using rotational energy to move fluid through the pump system, ensuring efficient and reliable operation. These pumps are designed with a liquid reservoir that enables them to expel air from the suction line, ensuring they can start and operate without manual priming. Typically employed in water applications, they excel in handling low viscosity fluids.

Another type is the self-priming positive displacement pump.

These pumps can handle fluids of varying viscosities – from thin liquids like water to thick substances like sludge. Because they are designed with tightly coupled mechanisms, they efficiently manage air pockets, making them ideal for industrial and sanitary applications.

Finally, consider the advanced self-priming vacuum-assisted pump. Combining vacuum technology with self-priming features, these pumps provide rapid priming, high efficiency, and robustness. They are particularly suited for dewatering and sewage applications, demonstrating reliability even when faced with challenging fluid conditions.

4. Advantages of Self-Priming Pumps

Self-priming pumps offer several significant advantages, making them indispensable in various industrial and sanitary applications. They are uniquely designed to automatically prime themselves, eliminating the need for manual intervention, which enhances operational efficiency.

Reliability and ease of maintenance are key strengths of self-priming pumps.

These pumps handle a wide range of liquids, including those with entrained gases or suspended solids, with exceptional efficiency. This versatility ensures that self-priming pumps are suitable for diverse applications, from moving water to handling corrosive chemicals.

Moreover, self-priming pumps are robust and durable, thanks to their construction that isolates the motor and critical components from corrosive and abrasive fluids. This design feature significantly prolongs the pump’s lifespan and reduces the likelihood of mechanical failures, making them a cost-effective solution over the long term.

5. Disadvantages of Self-Priming Pumps

While self-priming pumps offer many benefits, they do come with certain drawbacks that may affect their suitability for specific applications.

Firstly, self-priming pumps are generally less efficient compared to standard centrifugal pumps. The need to incorporate a liquid reservoir within the pump’s housing introduces internal clearances that increase energy consumption and reduce overall efficiency. This aspect can be particularly significant in energy-sensitive environments.

Another potential disadvantage is the requirement for initial priming fluid. Self-priming pumps cannot function without the special liquid in their reservoir, which means they might need to be filled manually if left idle for extended periods. This need for manual intervention can negate some of the automation benefits these pumps provide.

Finally, while self-priming pumps are more resilient to certain conditions, they can still face clogging issues. Despite their ability to handle solids, suction strainers are often necessary to prevent blockages. This adds another layer of complexity to their maintenance, particularly in environments with heavy particulate matter or viscous fluids.

6. Applications of Self-Priming Pumps

Self-priming pumps are incredibly versatile.

They are essential in industries where efficient liquid transfer is crucial, such as water treatment plants, food processing units, chemical industries, and mining operations. Their ability to handle intermittent operations without manual intervention makes them indispensable in many settings.

Municipalities rely on self-priming pumps.

For instance, they are used in sewage and wastewater management systems. Their robust construction allows them to handle slurries and solids without frequent maintenance issues.

Industrial and mining applications also benefit from these pumps. In cases where corrosive or hazardous liquids are involved, self-priming pumps ensure safe and efficient transfer by reducing the risk of leaks and spills. In mining, they are vital for dewatering operations, ensuring that work sites remain operational and safe.

In sum, self-priming pumps offer a reliable solution for various fluid handling needs. From large-scale agricultural irrigation to emergency dewatering during floods, and critical mining operations, their strategic application ensures operational success across multiple sectors.

7. Selecting the Right Self-Priming Pump

Selecting the right self-priming pump depends on specific operational requirements. Considerations such as flow rate, fluid viscosity, and the nature of solids present are crucial in making an informed decision.

Evaluate the environmental conditions where the pump will be used, ensuring it meets both technical and regulatory standards. It’s important to match the pump’s specifications to your application’s demands.

Consulting with industry experts and meticulously verifying pump features can significantly enhance your system’s efficiency.

7.1. Size of Solids

When selecting a self-priming pump, consider the size of solids it can effectively handle. Larger particles may clog or damage inappropriate pump models, compromising performance.

Efficient solid handling enhances the longevity and reliability of self-priming pumps.

Pumps with robust impellers and wide passageways are ideal for applications with large solids. Ensuring your pump can handle anticipated solid sizes prevents operational disruptions and costly maintenance.

7.2. Fluid Viscosity

The viscosity of the fluid significantly impacts the performance and selection of self-priming pumps.

Highly viscous fluids can increase the energy required for pumping operations and may demand more powerful pump models.

Pumps designed for low-viscosity fluids might not perform well with thicker substances, leading to inefficiencies or mechanical stress.

Choosing a pump with the correct impeller type and materials is critical for handling varying fluid viscosities effectively.

Always test the pump performance under real conditions to ensure consistent operation with the intended fluid viscosity.

7.3. Priming Distance

The priming distance is a crucial factor in determining the efficiency of a self-priming pump.

- Horizontal pipework: Assess any bends, strainers, or valves.

- Vertical runs: Include the height from the source to the pump.

- Pressure losses: Account for accessories and fittings.

- NPSHA (Net Positive Suction Head Available): Ensure there’s sufficient pressure.

Proper assessment of the priming distance can prevent issues such as cavitation, gravity-induced flow limitations, and vortexing.

It’s vital to confirm that designed flow is achievable at various heights and conditions.

7.4. Fluctuating Fluid Levels

Fluctuating fluid levels can impact the performance of self-priming pumps significantly.

- Assess Fluid Sources: Evaluate if fluids are drawn from tidal rivers, the sea, or tanks with varying levels.

- Ensure Sufficient NPSHA: Confirm that the Net Positive Suction Head Available is adequate at different heights.

- Check for Vortexing: Prevent air from being drawn in by ensuring proper submersion.

- Account for Vertical Variations: Design the system to handle varying vertical suction heights.

- Monitor Pressure Changes: Regularly monitor for changes that might affect pump efficiency.

- Install Anti-Vortex Devices: Consider employing devices to minimize the risk of vortex formation.

- Plan for Maintenance: Regularly inspect and maintain the pump to address any issues caused by fluctuating levels.

Adequate planning ensures that pumps can handle changing fluid levels without performance loss.

Incorporate anti-vortex devices and periodic maintenance to maintain optimal pump functionality.

7.5. Priming Time

Priming time is crucial for ensuring efficient pump operation without overheating or damage.

- Check Suction Line: Ensure it’s free from obstructions and leaks.

- Monitor Temperature: Recirculating fluid can heat up quickly.

- Evaluate System Components: Consider bends and valves that might affect priming time.

Proper system design helps minimize priming time and ensures effective operation.

Timely evacuation of air reduces wear on gaskets and seals, enhancing pump longevity.

7.6. Power Options

Choosing the right power options is crucial to ensure your centrifugal pump and self-priming pump operate effectively and efficiently.

For general applications, you might consider using an electric motor powered by either single-phase or three-phase electricity, depending on your facility’s supply. Electric motors are reliable, require minimal maintenance, and are suitable for both indoor and outdoor installations. Alternately, diesel engines can provide a robust, autonomous power source for remote or portable applications.

Hydraulically driven pumps are another option, offering precise control and high power density. They are ideal for applications requiring variable flow rates, and can be easily integrated into large, complex hydraulic systems commonly found in construction and industrial environments.

It is important to assess your operational needs carefully to choose the best power option. Consider factors such as the availability of electrical supply, the need for portability, and the specific demands of your application. Proper selection ensures optimal performance, longevity, and cost-efficiency of your self-priming pump system.

7.7. Close or Long Coupled

When choosing between close or long coupled pump designs, you should consider several critical factors.

- Cost-effectiveness: Close coupled designs are generally less expensive.

- Ease of maintenance: Long coupled units are easier to maintain and service.

- Space constraints: Consider the spatial limitations of your installation site.

- Operational robustness: Long coupled units often offer better alignment and less vibration.

- Pump lifespan: Long coupled designs typically enjoy a longer operational life.

- Ease of installation: Close coupled pumps are simpler to install in compact spaces.

- Power transmission efficiency: Long coupled pumps provide better power transmission.

Close coupled pumps are more compact and usually cheaper, making them suitable for cost-sensitive installations.

Long coupled pumps, due to their robust design, are preferable for demanding applications requiring longevity and easier maintenance.

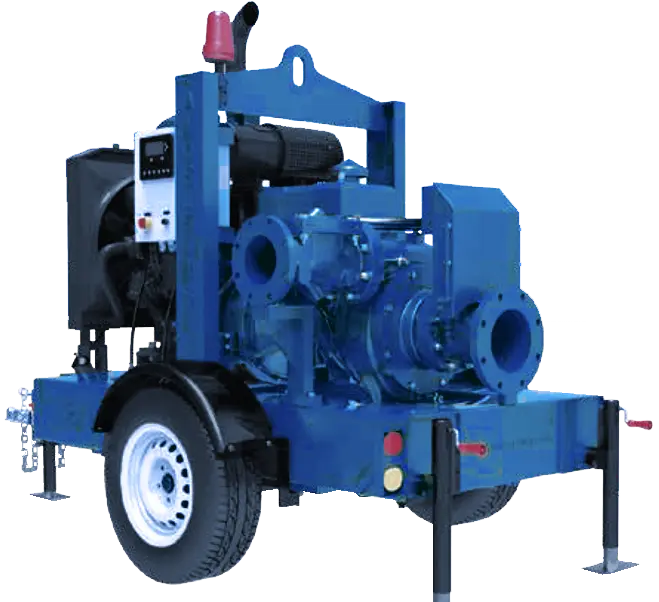

7.8. Trailer Mounted, Baseplate, or Pontoon Mounted

Deciding how to mount your self-priming pump is a crucial step in ensuring operational efficiency.

- Trailer Mounted: Best for mobility and ease of transportation.

- Baseplate Mounted: Ideal for stationary installation with robust stability.

- Pontoon Mounted: Suitable for dewatering applications in bodies of water.

Trailer-mounted pumps offer flexibility for rapidly changing project sites.

Baseplate-mounted pumps provide a sturdy foundation for stable, long-term operations.

Pontoon-mounted pumps excel in aquatic environments, ensuring constant pump performance even with fluctuating water levels.

7.9. Controls

Effective control systems are essential for the optimal operation of self-priming pumps.

You should consider automation options that align with the specific requirements of your operations.

Automated controls can simplify the starting and stopping processes, allowing for seamless operation and reducing manual intervention.

Integration with existing systems is crucial, ensuring that the new controls complement the overall process flow.

Investing in advanced control mechanisms can enhance efficiency and reliability significantly.

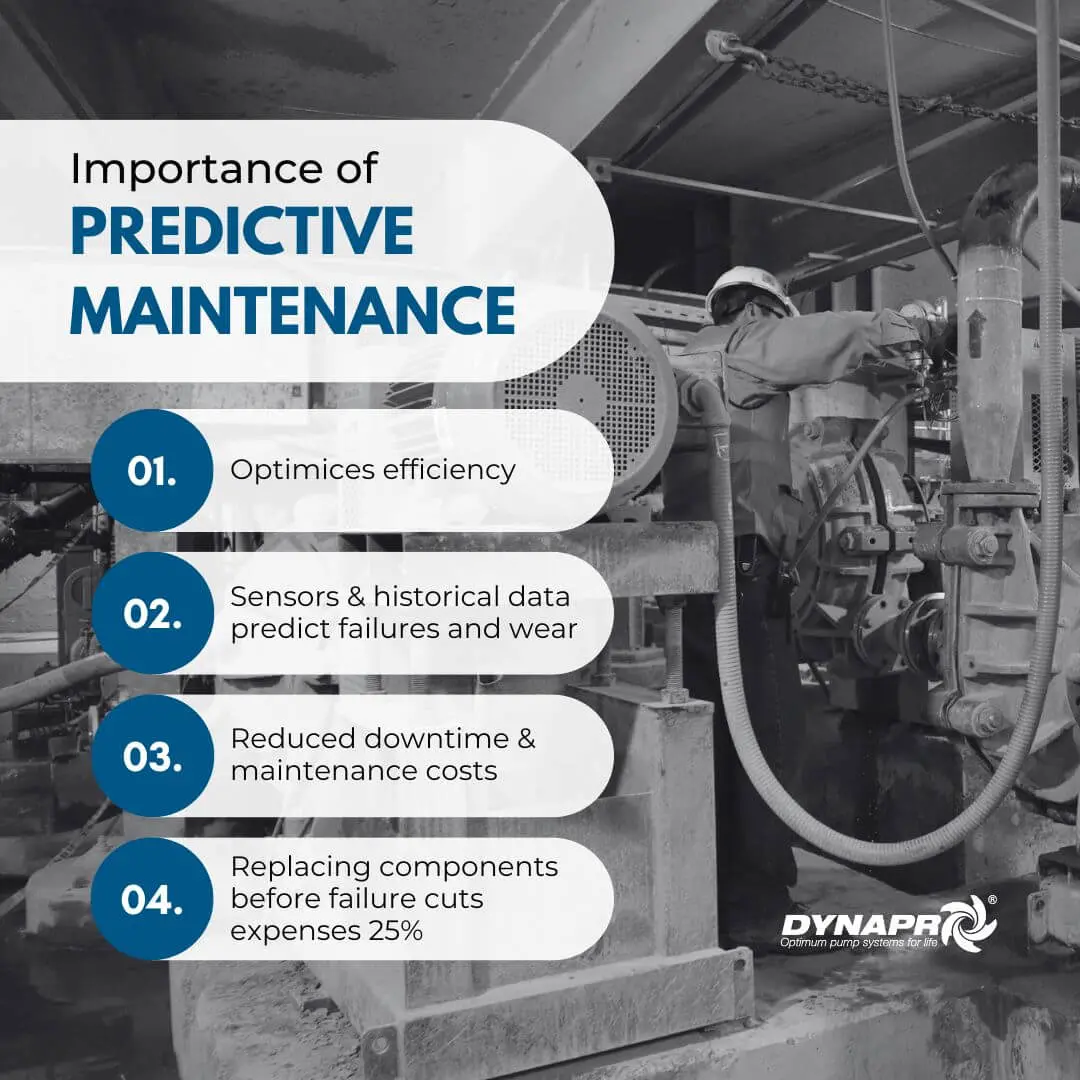

8. Maintenance Tips for Self-Priming Pumps

Regular maintenance is the cornerstone to ensuring the longevity and reliability of your self-priming pump.

You should perform frequent visual inspections to check for leaks, corrosion, or any unusual noises.

Ensure that the bearings are properly lubricated; maintaining the correct lubricant levels prolongs the pump’s operational life.

Check the pump’s alignment and look out for excessive vibrations, which could indicate underlying issues needing immediate attention.

Always keep a detailed maintenance log to track all performed actions and schedule future maintenance activities.

9. Troubleshooting Common Issues

Encountering issues with your self-priming pump can be frustrating, but many common problems have straightforward solutions. Understanding the root cause of these issues requires systematic inspection.

If your pump fails to prime, first check for air leaks in the suction line.

Inspect the suction line connections and gaskets for any visible signs of wear or damage.

Verify that the initial priming liquid is present, as its absence can impede the priming process.

Inconsistent flow or reduced performance might signal a clog in the impeller. Shut down the pump and inspect the impeller and volute for obstructions.

Excessive vibrations during operation can indicate misalignment or bearing wear. Ensure that all components are securely fastened and aligned correctly.

Remember, proactive maintenance and quick responses to irregularities are key to minimizing downtime. Contact a professional if issues persist despite troubleshooting efforts.

10. Installing a Self-Priming Pump

Installing a self-priming pump involves precise steps, ensuring optimal alignment, and creating a secure environment for the pump’s continuous operation.

Firstly, position the pump near the liquid source.

This positioning minimizes suction length and potential priming issues.

Check the suction lines thoroughly for any cracks or leaks.

Ensure the initial priming liquid fills the pump casing to the recommended level.

This liquid is essential for initiating the priming process and maintaining pump efficiency.

Finally, test the setup by starting the pump, verifying smooth operation and absence of air leaks.

11. Why Choose Our Self-Priming Pumps?

Choosing Dynapro self-priming pumps ensures unmatched performance and durability.

Our pumps are designed to handle challenging conditions, featuring an armoured volute that protects the main casing from abrasive wear and high-velocity impacts. Constructed in ductile iron, the impeller and casing offer robustness and longevity. These pumps manage tough fluids without compromising efficiency.

Built to last, our self-priming pumps handle solids up to 50 x 24mm in diameter, ensuring consistent flow rates and reduced maintenance. This reliability means fewer operational disruptions and lower long-term costs.

Investing in our self-priming pumps means partnering with a company that prioritizes your success. Contact our experts today to see how our pumps can enhance your system’s performance. Our core advantages:

- ECO-Friendly Vacuum Priming Innovation: The EVP system features advanced 3rd generation vacuum pump technology, enabling any centrifugal pump to complete priming within seconds. It offers high air processing capacity, strong vacuum, low operating temperature, and maintenance-free operation without the need for oil or mechanical seals.

- Prime-Sleep-Prime (P-S-P) Auto Switch System: The EVP system transitions to a sleep mode automatically once priming is complete. For general applications, the EVP system operates for a short duration, making daily maintenance or part replacement almost unnecessary throughout its lifecycle.

- Dry Running Protection System: Pumps can operate dry for extended periods without damaging their mechanical seals. This is due to a protection system comprising a standard mechanical seal, oil chamber, and oil reservoir connected by hoses to form an oil circulation loop. An optional air-cushion design on the mechanical seal’s stationary seat eliminates the need for oil lubrication during prolonged dry running. Alternatively, a set of lip seals can replace the mechanical seal, enhancing sealing effectiveness and simplifying maintenance.

- Advanced Cooling System: A pressurized cooling flush water is introduced from the centrifugal pump’s water passage into the vacuum pump’s water jacket, cooling the entire vacuum pump quickly and effectively. This pressurized water flow helps maintain a low operating temperature, significantly extending the EVP system’s lifespan.

- User-Friendly Disassembly Design: The vacuum pump’s cover can be easily removed from the non-drive end for inspection or replacement. The centrifugal pump’s impeller, wear ring, and mechanical seal are also accessible without removing the diesel engine or pump frame, facilitating straightforward maintenance.

- Innovative Non-Clogging Impeller: Equipped with wide water passage impellers that can handle solids with a diameter of 3” or larger. These pumps are ideal for critical applications like sewage, sludge, and fluids containing large stones.

- Self-Cleaning Mechanism: The stuffing box features a unique structure that mixes and discharges solids. Small solids or sand entering the stuffing box are mixed by built-in mixers and expelled using the centrifugal force of the impeller back vanes, preventing clogging of the mechanical seal spring and avoiding seal failures.

- Versatile Technology: The powerful EVP Priming System is versatile and suitable for various fluid industry applications, including dewatering, bypass, firefighting, lift station backup, mining, irrigation, water transfer, and well point systems.

12. People Also Ask on Self-Priming Pumps

How do self-priming pumps operate?

Self-priming pumps automatically evacuate air from the suction line and prime themselves.

Are self-priming pumps maintenance-intensive?

No, they generally require less maintenance compared to submersible pumps.

What industries benefit most from self-priming pumps?

Industries such as wastewater treatment, chemical processing, mining, and food and beverage processing benefit significantly.

Can self-priming pumps handle solids?

Absolutely, many self-priming pumps are designed to handle solids, making them versatile for various applications and reducing the risk of clogging. This versatility often leads to improved efficiency and greater reliability in challenging operating environments.

What is self-priming method?

Self-priming is a method whereby a pump can clear its suction line of air and continue pumping without needing external priming. This is achieved through a specially designed pump mechanism that retains fluid in a reservoir within the pump body.

Once initiated, the pump circulates this retained fluid, creating a vacuum that draws air out of the suction line. This continuous circulation not only eliminates air pockets but also ensures that the fluid begins to flow smoothly through the system.

In many industries, the self-priming method is particularly valuable for its efficiency and reliability. These pumps can handle intermittent operations without requiring manual intervention to restart.

They are especially beneficial in settings where pumps might frequently stop and start, as the built-in reservoir maintains the priming liquid necessary for operation. This method significantly reduces downtime and maintenance efforts.

Furthermore, pumps utilizing the self-priming method often incorporate advanced technologies to enhance their functionality. These innovations include dry running protection, non-clogging impellers, and eco-friendly vacuum systems.

Overall, the self-priming method offers a seamless and effective solution for maintaining consistent pump operations, even in challenging conditions. This capability ensures that processes run smoothly, maintaining productivity and reducing manual workload.