Have you ever considered the crucial role of efficient dewatering in construction success? Effective construction dewatering isn’t just about removing water; it’s about transforming challenges into opportunities.

It mitigates delays and enhances site safety.

With adeptly managed dewatering strategies, including proper handling of sludge, you ensure not only project efficiency but also fortify the foundation of your construction endeavors.

1. Understanding Dewatering

Successfully managing water with construction dewatering pumps is paramount to construction success. You’ve likely encountered situations where water challenges your project’s progress, and this is where dewatering comes in.

Dewatering involves the strategic removal of water, and methods such as eductor wells play a vital role in this process.

When undertaken properly, using dewatering pumps ensures the stability and integrity of your construction site. Efficient dewatering is not merely a procedural necessity; it’s a cornerstone of project management that fosters timely, cost-effective, and safe operations.

By grasping the nuances of dewatering, including the use of eductor wells and sedimentation control, you position yourself to conquer the trials of site water management. Whether through advanced pumps, drainage systems, or wellpoints, you gain the acumen to eliminate water-related obstacles and advance your projects with confidence and precision. Effective dewatering is your pathway to transforming potential setbacks into streamlined, well-executed ventures.

2. Methods of Dewatering

In dewatering processes, a variety of methods exist, each tailored to specific site requirements, including the effective management of sludge. Permeable soil conditions may benefit from the employment of wellpoint systems, which effectively lower groundwater levels. Alternatively, utilizing sump pumps allows you to address localized water accumulation, providing a flexible solution for diverse environmental conditions. Advanced techniques, such as deep well dewatering, offer robust options for intensive projects, ensuring comprehensive water removal and maintaining the integrity of your site operations. By mastering these methods and incorporating effective slurry management, you empower yourself to navigate and mitigate water challenges with precision and efficiency.

2.1. Sump Pumping

In construction, sump pumping serves as a cornerstone of effective dewatering, helping manage water accumulation. Utilizing this method ensures you keep your site dry and operational.

To deploy a sump pump, you must first excavate a sump hole where water collects. Place the pump in this sump to efficiently expel water to a designated area.

Sump pumps are highly efficient, capable of removing thousands of gallons per hour.

Regular maintenance is essential: clear debris from the sump hole and check the pump’s functionality. By doing so, you secure ongoing dewatering performance and minimize project delays. Properly executed, sump pumping enhances your construction efficiency and reliability.

2.2. Well Points

Well points offer a targeted approach to construction site dewatering that is both reliable and adaptable, making them invaluable in achieving your dewatering goals.

Installing well points involves strategically placing small-diameter wells around the excavation site.

These wells are connected to a header pipe, which is then attached to a vacuum pump. This setup ensures efficient water removal, maintaining optimal ground conditions and preventing water from entering the excavation area.

The well point system excels in areas with fine-grained soils. By creating a continuous water extraction cycle, it lowers the groundwater level and supports stable, dry ground for safe and productive construction activities. Overall, well points are a dependable solution to your comprehensive dewatering strategy.

2.3. Deep Well Systems

Deep well systems excel in high-water table areas.

The system employs a series of strategically placed deep wells. Each well contains a submersible pump designed to remove large volumes of water, ensuring construction activities can proceed without delay. Notably, deep well systems are effective for lowering groundwater levels in highly permeable soils like gravel and sand.

This method offers consistent water level control.

Deep well systems provide an unparalleled dewatering solution – not only do they handle vast water quantities efficiently, but they also maintain a steady and reliable water table reduction around your site perimeter.

While setting up and monitoring these systems requires a more sophisticated approach, your investment in deep well systems promises significant returns in terms of enhanced productivity and site safety. Proper management of your deep well system ensures optimal dewatering conditions, contributing to the success and timely completion of your construction project.

2.4. Vacuum Dewatering

Vacuum dewatering is highly efficient.

Vacuum dewatering involves the use of suction to remove water. This method utilizes a series of vacuum pumps connected to header pipes, which are inserted into the ground. Consequently, water is drawn upward and discharged away from the construction site, ensuring a dry work environment.

Small volumes can be tackled effectively.

The primary advantage of vacuum dewatering, a vital construction dewatering method, is its suitability for varied soil types and confined spaces, where other methods might falter. This is particularly valuable for urban projects.

You will find vacuum dewatering to be indispensable in scenarios requiring rapid response and minimal disruption. By choosing this method, your site benefits from accelerated drying times, reduced soil settlement issues, and enhanced ground stability, paving the way for successful project outcomes.

3. Benefits of Dewatering

Dewatering offers numerous advantages.

First and foremost, dewatering ensures a stable work environment. This stability allows you to conduct your construction activities without the looming threat of unexpected water ingress. Consequently, your team can work more efficiently, avoiding delays and reducing the risk of accidents caused by waterlogged conditions.

Wet sites increase hazards.

Moreover, dewatering enhances structural integrity. By efficiently removing water, you prevent soil erosion and reduce hydrostatic pressure, which are crucial for maintaining the foundational strength needed for any structure.

You also gain significant cost savings. As the construction site remains dry, heavy machinery and workers can operate without obstacle, rendering operations smoother and less costly. Not only does this improve overall productivity, but it also establishes a safer, more reliable environment that fosters long-term project success.

4. Dewatering Equipment

Selecting the right dewatering equipment can dramatically improve efficiency, lower costs, and ensure a successful project outcome.

Different site conditions require different dewatering methods.

Pumps, often the backbone of dewatering, come in various types (submersible pumps, centrifugal pumps).

Understanding each type’s functionality can help you determine the most suitable for your specific needs.

On the other hand, wellpoints are indispensable for shallow trench excavations, offering rapid water removal.

Lastly, sand drains, a less common but effective method, prove useful for consolidating loose, water-saturated soils through vertical drainage. Choose your equipment judiciously to transform your site into a dry, efficient workspace.

5. Safety Precautions

Ensuring safety during the dewatering process should be your top priority.

In 2016, OSHA reported, a significant number of construction-related incidents were due to unsafe dewatering practices. Adhering to strict safety protocols can minimize such risks and guarantee a safer worksite.

First, it’s crucial that you provide adequate training for all personnel involved in the dewatering operations. Ensuring they are well-versed in the equipment and safety procedures can significantly mitigate workplace accidents.

Additionally, you should consistently monitor site conditions. This includes regular inspections of the dewatering equipment, as well as ongoing assessments of soil stability and water levels, preventing unforeseen hazards.

Remember, your vigilance and commitment to safety are paramount in creating a secure, efficient, and successful dewatering operation.

6. Environmental Considerations

When planning your dewatering process, assessing the environmental impact is crucial.

Firstly, you must evaluate the water’s quality to ensure that discharging it won’t harm any nearby ecosystems. Contaminants such as oils, chemicals, or sediments can pose severe threats to the local flora and fauna, necessitating proper filtration or treatment before discharge.

Moreover, be mindful of the potential for soil erosion and sedimentation in your disposal area. This can cause significant damage to the landscape and may result in sediment-laden runoff contaminating nearby water bodies.

By incorporating sustainable practices into your dewatering strategy, you can minimize adverse environmental effects and demonstrate your commitment to responsible construction. This approach not only protects surrounding ecosystems but also enhances your project’s reputation and long-term success.

7. Cost Factors in Dewatering

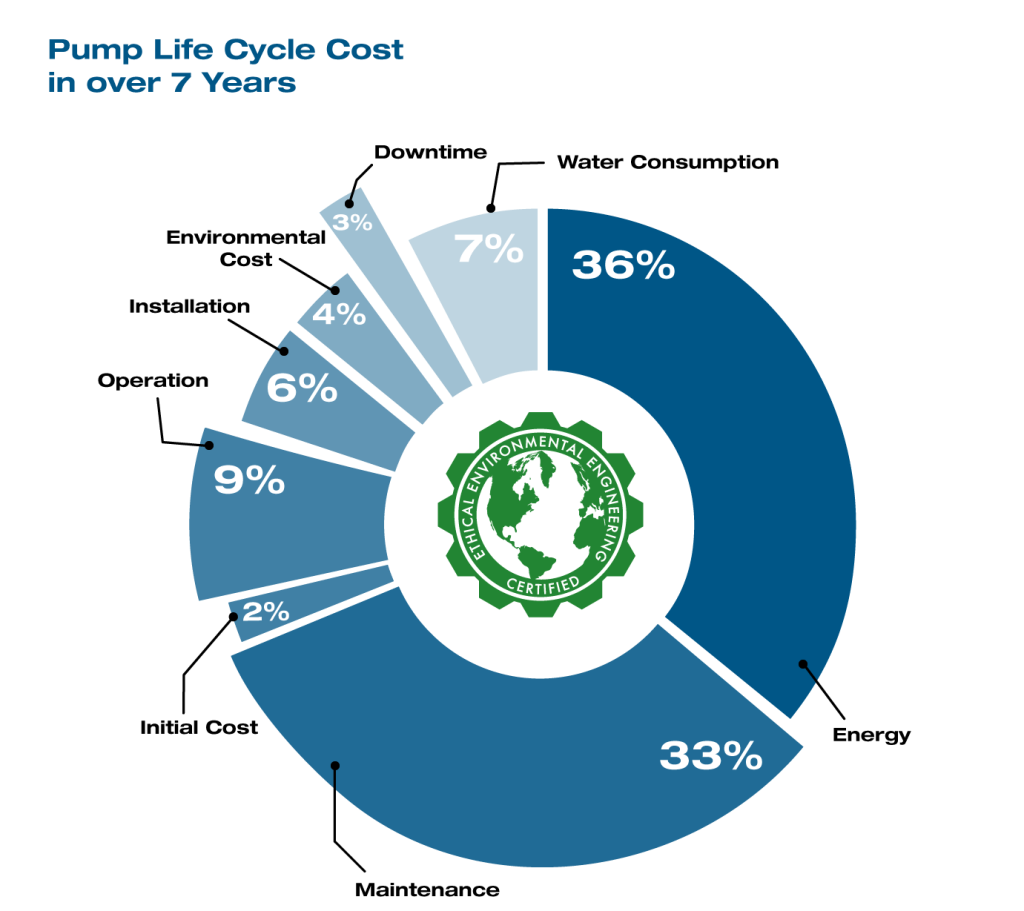

Several elements influence the overall cost of dewatering your construction site.

Firstly, the complexity and scale of your project play a crucial role. Larger sites with deeper excavations naturally incur higher dewatering expenses due to the increased equipment and manpower needed.

Equipment choice is another significant cost determinant. Advanced, high-efficiency pumps and filtration systems can have steep initial costs, although they may offer long-term savings through reduced operational expenses.

Labor costs cannot be overlooked either. Skilled workers proficient in dewatering techniques are essential for ensuring an efficient and safe process, and their expertise comes at a premium.

Lastly, always consider the potential environmental compliance expenses. Stricter regulations may require additional treatments, increasing both direct and indirect costs.

8. Case Studies

Exploring real-world applications of dewatering techniques can provide valuable insights into best practices and innovative solutions.

One such example is a high-profile construction project in New York City, where dewatering was critical for the success of deep foundation work. The team implemented a series of wellpoints and sump pumps to efficiently lower the groundwater table, ensuring safe and dry excavation.

In another instance, a coastal infrastructure project in Florida faced unique challenges due to the high water table. By employing a combination of vertical dewatering wells and horizontal drainage systems, the project team managed to maintain a stable work environment and minimize delays.

These examples underscore the importance of tailoring dewatering strategies to specific site conditions. By leveraging advanced technology and customized approaches, you can overcome obstacles, streamline processes, and drive your project toward successful completion with minimal disruption and maximum efficiency.

9. Dewatering Best Practices

First and foremost, ensure you conduct a thorough site assessment before dewatering begins. This will pinpoint potential issues and guide your strategy for optimal results.

Always use appropriate equipment that suits the specific site conditions.

Remember, regular maintenance of dewatering systems is crucial. Continuous monitoring ensures efficiency and helps you quickly address any anomalies, maintaining smooth operations.

Be mindful of environmental regulations and strive for eco-friendly practices. By integrating sustainable solutions and adhering to legal requirements, you not only protect the environment but also enhance your project’s reputation and success. This dual focus can motivate your team, galvanize support from stakeholders, and ultimately contribute to broader industry advancements.